Demand Planning & Forecasting

In the complex realm of supply chain management, the ability to accurately predict demand and plan accordingly is vital for sustained growth. ASC Software’s Demand Planning & Forecasting tool offers businesses the advantage of data-driven insights, ensuring a proactive approach to market dynamics. Utilizing historical data, current market trends, and advanced algorithms, our system delivers forecasts that are both precise and actionable. Tailored for established enterprises looking to optimize their operations as well as those seeking a more robust solution they can grow with, our tool is geared towards ensuring you’re always aligned with market demand, optimizing inventory levels, and enhancing profitability.

Historical Data Analysis

Leveraging past performance to predict future demand is a cornerstone of effective forecasting. ASC Software’s ASCTrac system delves deep into historical sales and order data, identifying patterns and trends that can inform future predictions. This retrospective analysis provides a solid foundation upon which accurate forecasts can be built, ensuring that businesses are always prepared for market fluctuations. By integrating these insights with current market dynamics, businesses can achieve a more holistic view of their demand landscape, enabling them to make proactive decisions and optimize inventory management strategies.

Advanced Forecasting Algorithms

Beyond historical data, our system employs sophisticated algorithms that factor in a myriad of variables, from seasonal trends to promotional activities. These algorithms ensure that the forecasts generated are not only accurate but also actionable, providing businesses with a clear roadmap for inventory management and production planning. By continuously refining and adapting to new data inputs, these algorithms position businesses at the forefront of demand planning software, ensuring they’re always equipped to respond to market dynamics effectively.

Multi-location Forecasting

For businesses operating across multiple locations or regions, understanding demand variations is crucial. Our system provides multi-location forecasting capabilities, allowing businesses to generate location-specific forecasts. This granularity ensures that inventory and production decisions are tailored to the unique demand patterns of each location. By catering to the specific needs of each region, businesses can optimize their operations, ensuring customer satisfaction and efficient resource allocation across the board.

Seasonal Demand Forecasting

Understanding seasonal fluctuations is crucial for businesses that experience peaks and troughs in demand throughout the year. ASC’s ASCTrac system is adept at identifying these seasonal trends, allowing businesses to plan their inventory and production schedules accordingly. This ensures optimal stock levels during peak seasons and avoids overstocking during off-peak times. By aligning production and procurement strategies with these forecasts, businesses can maximize sales opportunities and reduce holding costs, leading to improved bottom-line results.

Collaborative Forecasting

Collaboration is key to achieving a holistic view of demand. ASC Software facilitates collaborative forecasting by allowing multiple stakeholders, from sales to production teams, to contribute their insights. This collective intelligence ensures a more rounded and accurate forecast, taking into account perspectives from different areas of the business. By fostering a culture of collaboration, businesses can ensure that all potential demand drivers are considered, leading to more informed decision-making.

Integration with Production Scheduling

An accurate demand forecast is only as good as its execution. ASCTrac ensures that the insights from demand planning are seamlessly integrated into production scheduling. This ensures that production is always aligned with market demand, optimizing resource utilization and reducing wastage. With this tight integration, businesses can ensure a smooth flow from forecasting to production, enhancing operational efficiency and customer satisfaction.

Customizable Forecasting Models

Every business is unique, and so are its forecasting needs. That’s why ASCTrac offers customizable forecasting models, allowing businesses to tailor the system to their specific requirements. Whether it’s adjusting for industry-specific trends or incorporating business-specific data, our tool is flexible enough to accommodate. This adaptability ensures that forecasts are always aligned with the unique nuances of each business, leading to more accurate and relevant predictions.

Real-Time Data Integration

In the dynamic landscape of business, real-time data plays a pivotal role in making informed decisions. ASC Software’s Demand Planning & Forecasting tool integrates real-time data from various sources, ensuring that forecasts are always based on the most current information. This real-time integration ensures that any sudden market changes or unexpected demand drivers are immediately factored into the forecasts. By continuously updating the forecasting models with fresh data, businesses can react swiftly to changing circumstances, ensuring they remain agile and responsive to market needs.

Product Lifecycle Forecasting

Every product has its lifecycle, from introduction to decline. ASC’s ASCTrac factors in the lifecycle stage of products, ensuring that forecasts are aligned with expected demand patterns for new launches, mature products, or those nearing the end of their lifecycle. By understanding and predicting the demand nuances associated with each lifecycle stage, businesses can make more informed inventory, marketing, and production decisions, maximizing profitability for each product.

Still have questions? Contact ASC Software today to setup a call or demo Contact Us

Recent Blogs

Essential Manufacturing KPIs for Optimizing Performance

Reading time: 10 minutes In the realm of manufacturing, Key Performance Indicators (KPIs), also known as manufacturing KPIs, can make or …

The Cost of Automated Storage and Retrieval Systems

Reading time: 8 minutes Discover what automated storage and retrieval systems really cost and how they can pay off for your …

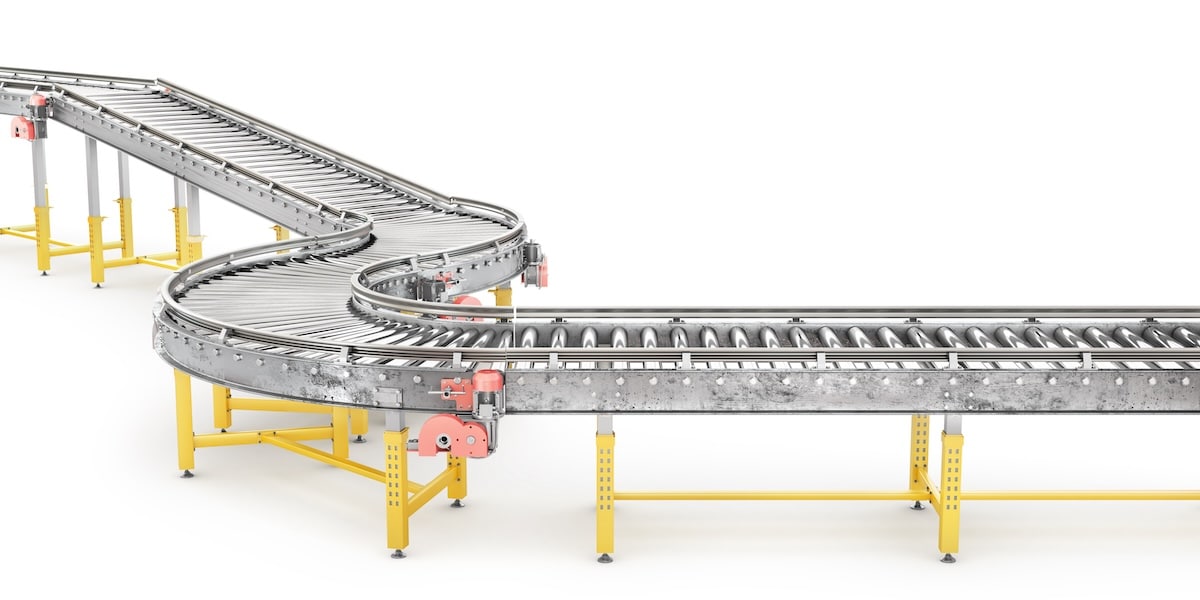

Reading time: 7 minutes Discover how conveyor systems revolutionize warehouse operations, optimizing efficiency and productivity. The Role of Conveyor Systems in …