Production Scheduling

Real-Time Production Monitoring

In the fast-paced environment of manufacturing, having immediate insights into your production processes is invaluable. ASCTrac provides a platform where you can monitor ongoing tasks, track their progress, and swiftly identify any bottlenecks. This real-time monitoring ensures that you’re always in control, allowing for timely interventions and optimal resource allocation. By having a bird’s-eye view of the entire production line, managers can make informed decisions, ensuring that every step of the process is optimized for maximum efficiency.

Demand-Driven Scheduling

Understanding and predicting demand is a cornerstone of efficient production. Our system doesn’t just react; it proactively analyzes demand patterns and adjusts your production schedule accordingly. This foresight ensures that production aligns with market needs, reducing inventory holding costs and preventing overproduction. By producing what’s needed when it’s needed, businesses can enhance customer satisfaction, ensuring that products are always available without unnecessary delays.

Resource Optimization

Resources, whether they’re machinery, manpower, or materials, are the backbone of any production process. ASCTrac’s intelligent system ensures that these resources are allocated in the most efficient manner. By analyzing the production requirements and matching them with available resources, the system reduces wastage and ensures that there’s minimal downtime. This level of optimization ensures that businesses get the maximum output from their resources, leading to higher profitability and reduced operational costs.

Seamless Integration with Inventory

Production and inventory are two sides of the same coin. A disconnect between them can lead to inefficiencies and increased costs. ASCTrac Software bridges this gap with a seamless integration between a production schedule and inventory management. This integration ensures that the required materials for production are always available. Simultaneously, as products get manufactured, the inventory gets updated in real-time, ensuring that there’s always an accurate record of stock levels. This harmony between production and inventory leads to smoother operations and reduced chances of stockouts or overproduction.

Prioritization Capabilities

In any production environment, there will always be tasks that are more urgent than others. ASCTrac recognizes this and allows for dynamic rescheduling based on priorities. Whether it’s an urgent order that needs to be fulfilled or a high-value client whose requirements need to be prioritized, our system ensures that these tasks are addressed promptly. This dynamic prioritization ensures that high-priority tasks are completed without disrupting the overall flow of the production process.

Predictive Analytics

In today’s competitive market, merely reacting to situations isn’t enough. Businesses need to anticipate future trends and challenges. ASCTrac’s advanced analytics tools provide insights into potential demand surges, resource shortages, and other challenges. By analyzing past data and current market trends, our system can make accurate predictions about future production needs. This foresight allows businesses to prepare in advance, ensuring that they’re always a step ahead of the competition.

Scalable, Multi-Site Solution

As businesses grow, their production needs to evolve. What works for a small-scale manufacturer might not be suitable for a large enterprise. ASC Software is designed to scale with your business. Whether you’re increasing your product lines, expanding to new locations, or ramping up production volumes, our software can handle it. This scalability ensures that as your business grows, your production processes remain efficient and optimized.

Automated Alerts

In the complex world of production, there are countless variables to keep track of. Missing out on a crucial update can lead to significant disruptions. ASC Software’s automated alert system ensures that you’re always informed about vital production milestones, potential delays, or resource shortages. These proactive alerts allow for timely interventions, ensuring that the production process remains smooth and efficient. Whether it’s a machine that’s due for maintenance or a raw material that’s running low, our system ensures that you’re always in the loop.

Customizable Workflows

Every business is unique, with its own set of challenges and requirements. A one-size-fits-all approach to production can lead to inefficiencies. Recognizing this, ASC Software allows businesses to customize their production workflows. Whether it’s a specific sequence of tasks for a particular product line or a unique resource allocation strategy, our system can be tailored to fit these requirements. This flexibility ensures that the software aligns perfectly with your operational strategies, leading to optimized production processes.

Historical Data Analysis

The past can provide valuable insights into the future. By analyzing past production trends, businesses can identify patterns, strengths, and areas of improvement. ASCTrac provides tools that allow for a deep dive into historical production data. Whether it’s identifying seasonal demand trends or understanding resource utilization patterns, this historical data analysis provides insights that can drive future production strategies. By learning from the past, businesses can make informed decisions that enhance their future operations.

Shift and Workforce Management

Manpower is one of the most crucial resources in any production process. Efficiently managing shifts, allocating the workforce based on production needs, and ensuring optimal utilization are vital for maintaining high productivity levels. Overburdening employees can lead to fatigue, reduced output quality, and increased chances of errors. ASCTrac ensures that manpower is allocated optimally, with shifts being scheduled in a way that ensures consistent output without overburdening the workforce.

Supplier Coordination

Raw materials are the foundation of any production process. Delays in raw material deliveries can lead to production halts, increased costs, and missed deadlines. ASCTrac integrates supplier schedules with production, ensuring that raw materials are always available when needed. This coordination reduces the chances of production delays due to material shortages and ensures that the production process remains smooth and efficient.

Maintenance Scheduling

Machinery and equipment are the workhorses of any production process. Ensuring that they’re always in optimal condition is crucial for maintaining consistent output quality and reducing unplanned downtimes. ASCTrac integrates maintenance schedules with production, ensuring that machinery is always well-maintained. This integration reduces the chances of production halts due to equipment breakdowns and ensures that the production process remains smooth.

Still have questions? Contact ASC Software today to setup a call or demo Contact Us

Recent Blogs

Understanding Food Traceability Requirements for Retailers

Reading time: 10 minutes Suppliers aiming to meet food traceability requirements for major retailers must ensure a transparent supply chain to …

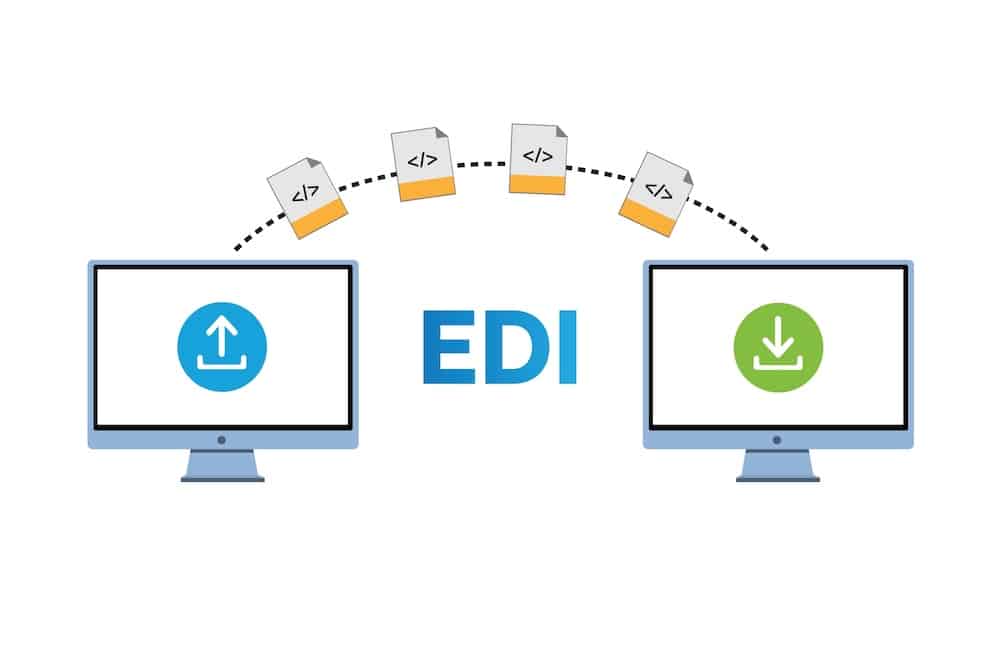

Mastering EDI Compliance for Retailers

Reading time: 11 minutes Mastering EDI (Electronic Data Interchange) is crucial for vendors to excel in business dealings with major big-box …

Reading time: 7 minutes Struggling to hit the sweet spot between meeting market demand and maintaining efficient production? Manufacturing capacity planning …