Receiving

In modern warehousing, the process of receiving goods sets the tone for all subsequent operations. ASC Software’s ASCTrac Warehouse Management System is equipped with robust receiving functionality, ensuring that every item entering the warehouse is accurately logged, inspected, and routed. This functionality is not just a feature; it’s the foundation for efficient inventory management, order processing, and shipping. With ASCTrac’s advanced receiving tools, warehouses can ensure accuracy, speed, and compliance from the very first step.

Advanced Barcode, RF and RFID Scanning

The cornerstone of efficient warehouse receiving is accurate item identification. ASCTrac integrates advanced barcode and RFID scanning capabilities, ensuring that every item is quickly and accurately logged upon arrival. This precision reduces manual data entry, minimizes errors, and speeds up the receiving process. By leveraging the latest in scanning technology, ASCTrac ensures that warehouses can handle large volumes of incoming goods without compromising on accuracy. This feature is particularly beneficial for warehouses that deal with diverse product ranges, as it ensures that every item, regardless of its size or packaging, is correctly identified and logged.

Customizable Receiving Workflows

Every warehouse has its unique warehouse receiving processes. That’s why ASCTrac was designed to offer customizable workflows, allowing warehouses to tailor the receiving process to their specific needs, ensuring efficiency and accuracy. By offering this level of customization, ASCTrac ensures that warehouses can optimize their receiving operations, reduce manual interventions, and ensure that all incoming goods are processed according to their specific requirements.

Integration with Transportation Management

Receiving operations are closely tied to transportation. Because of this, ASC’s system integrates with transportation management tools, ensuring that incoming shipments are tracked, scheduled, and processed efficiently. This integration is crucial for warehouses that rely on third-party logistics providers, as it ensures that incoming shipments are coordinated with transportation schedules, reducing delays and ensuring smooth warehouse receiving operations.

Automated Goods Receipt

Upon scanning, the system automatically generates a goods receipt, documenting the details of the received items. This automation ensures that all relevant data, from supplier details to lot numbers, is accurately captured. This not only provides a solid foundation for subsequent inventory and order processing operations but also ensures that any discrepancies between ordered and received goods are immediately flagged. By automating this crucial step, ASCTrac helps warehouses reduce administrative overheads, minimize errors, and ensure that all incoming goods are correctly accounted for.

Cross-Docking Capabilities

For warehouses practicing cross-docking, ASC’s ASCTrac system offers advanced features that allow received goods to be directly routed for shipping, reducing storage needs and speeding up order fulfillment. This feature is particularly beneficial for warehouses that handle fast-moving consumer goods, as it ensures that products are quickly routed to their final destination, reducing storage costs and ensuring timely deliveries.

Real-time Inventory Updates

As goods are received, ASCTrac updates the inventory in real-time. This ensures that stock levels are always accurate, providing a reliable foundation for order processing, inventory management, and procurement operations. This real-time update is crucial for warehouses that handle high volumes of goods, as it ensures that inventory levels are always in sync with actual stock, reducing the risk of stockouts or overstocking.

Quality Inspection Integration

Not all received goods are fit for inventory. That’s why ASCTrac integrates quality inspection workflows, allowing warehouse personnel to inspect incoming shipments, log quality metrics, and segregate items that don’t meet set standards. This rigorous inspection process ensures that only quality goods make their way into the inventory, reducing returns and enhancing customer satisfaction. By embedding quality checks into the receiving process, ASCTrac ensures that warehouses can maintain high inventory standards, reduce wastage, and build strong supplier relationships based on consistent quality.

Supplier Performance Tracking

Building strong supplier relationships is crucial for smooth warehouse operations. With every received shipment, ASCTrac logs supplier performance metrics, from punctuality to accuracy. Over time, these metrics provide insights into supplier reliability, allowing warehouses to identify top-performing suppliers and negotiate better terms. This feature is particularly beneficial for warehouses that rely on multiple suppliers, as it provides a centralized platform for tracking supplier performance, identifying trends, and making informed procurement decisions.

Batch/Lot Management

For industries where traceability is crucial, ASCTrac offers advanced batch and lot management features. Every received item can be tagged with its batch or lot number, ensuring traceability throughout its warehouse journey, from storage to shipping. This granular level of tracking is essential for industries like pharmaceuticals and food processing, where product recalls can have significant implications. By embedding batch and lot tracking into the receiving process, ASC software ensures that warehouses can quickly trace products back to their source, handle recalls efficiently, and maintain compliance with industry regulations.

Returns Management

Receiving isn’t just about new shipments; it’s also about handling returns. ASCTrac offers a robust returns management feature, ensuring that returned goods are processed efficiently, restocked or disposed of appropriately, and that all associated data is accurately logged. This feature is particularly beneficial for e-commerce warehouses, where returns are a common occurrence. By streamlining the returns process, ASCTrac ensures that warehouses can quickly process returned goods, update inventory levels, and provide timely refunds or replacements to customers.

Integration with Purchase Orders

Receiving is closely tied to procurement. ASCTrac allows for seamless integration with purchase orders, ensuring that received shipments are cross-referenced with open orders, discrepancies are flagged, and procurement teams are updated in real-time. This integration is crucial for warehouses that handle large volumes of orders, as it ensures that any discrepancies between ordered and received goods are immediately addressed, reducing the risk of stockouts or overstocking.

Damage and Discrepancy Reporting

Not all shipments arrive in perfect condition. That’s why ASCTrac allows warehouse personnel to log damages, discrepancies, and missing items, ensuring that issues are documented, suppliers are notified, and corrective actions are initiated. This feature is crucial for warehouses that handle fragile or perishable goods, as it ensures that any damages or discrepancies are immediately addressed, reducing wastage and ensuring accurate inventory levels.

Real-Time Dashboards

For decision-makers, having a real-time overview of receiving operations is crucial. Crucially, ASCTrac offers real-time dashboards, providing insights into receiving volumes, supplier performance, quality metrics, and more. By offering these insights, ASC Software ensures that decision-makers have all the information they need to optimize warehouse receiving operations, address any challenges, and drive continuous improvement.

Still have questions? Contact ASC Software today to setup a call or demo Contact Us

Recent Blogs

Understanding Food Traceability Requirements for Retailers

Reading time: 10 minutes Suppliers aiming to meet food traceability requirements for major retailers must ensure a transparent supply chain to …

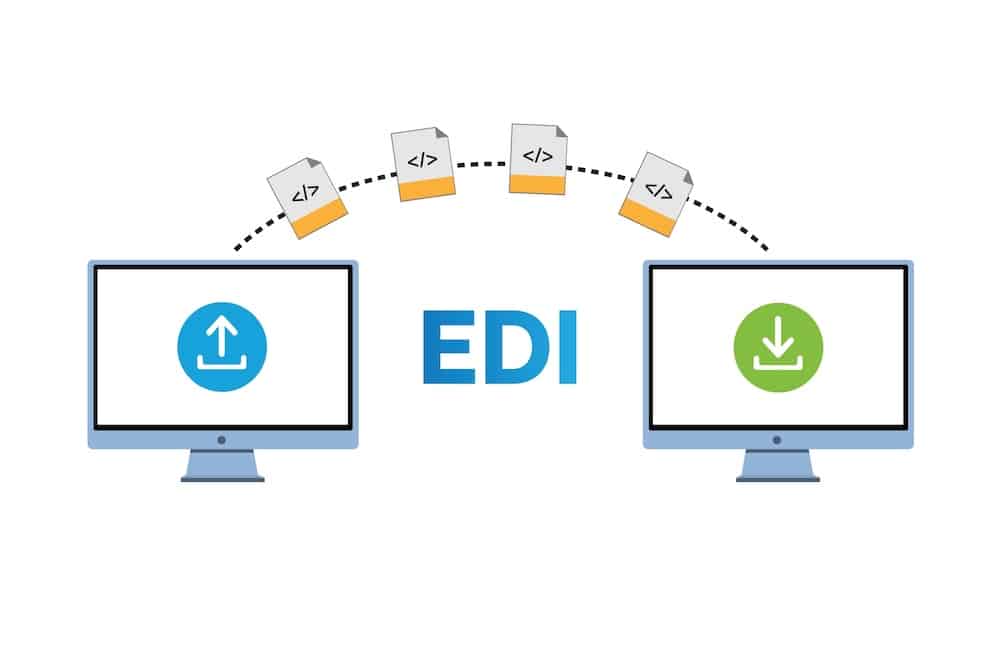

Mastering EDI Compliance for Retailers

Reading time: 11 minutes Mastering EDI (Electronic Data Interchange) is crucial for vendors to excel in business dealings with major big-box …

Reading time: 7 minutes Struggling to hit the sweet spot between meeting market demand and maintaining efficient production? Manufacturing capacity planning …