Putaway

Efficiently transitioning goods from the receiving dock to their designated storage locations is a cornerstone of seamless warehouse operations. ASC’s ASCTrac Putaway Feature is meticulously crafted to optimize this crucial step. By guiding warehouse personnel with intelligent suggestions and workflows, our system ensures that goods are stored efficiently, maximizing space utilization and setting the stage for the next phases of their warehouse journey.

FIFO, LIFO, and FEFO Support

Different goods have different storage requirements. Whether you operate on a First-In-First-Out, Last-In-First-Out, First-Expiry-First-Out basis, or First-Produced-First-Out, our system can accommodate these methodologies, ensuring goods are stored and retrieved in a manner that aligns with their characteristics. This flexibility is crucial for warehouses that handle a diverse range of products. For instance, perishable goods might be best managed using a FEFO approach, ensuring that items nearing their expiry date are dispatched first. On the other hand, items like electronics or apparel might be managed using a FIFO approach, ensuring that older stock is dispatched before newer stock.

Rules-Based Workflows

Every warehouse has its unique operational nuances. ASCTrac’s Putaway Feature allows managers to set specific rules that dictate putaway processes. Whether it’s prioritizing certain goods, designating zones for specific items, or setting temperature requirements, our system can adapt to your warehouse’s specific needs. These rules can be as broad or as granular as needed, allowing for a high degree of customization. For instance, if a particular product line requires cold storage, rules can be set to ensure this happens consistently. Over time, these rule-based workflows can significantly reduce manual intervention, ensuring that putaway operations are both fast and error-free.

Real-Time Inventory Updates

As items are put away, it’s crucial to update inventory levels in real-time. Our system ensures that as goods are stored, inventory counts are automatically adjusted, providing an accurate picture of stock levels at all times. This real-time update is not just a numerical exercise; it has profound implications for other warehouse operations. For instance, accurate inventory levels can inform purchasing decisions, ensuring that stock levels are optimized. Additionally, by having a real-time view of inventory, warehouse managers can make informed decisions about storage space allocation, ensuring that no space is wasted.

Optimized Pick Paths

Efficient putaway is not just about storage; it’s also about setting the stage for efficient picking. By considering future pick paths, our system suggests putaway locations that will streamline future order picking processes, reducing travel time and enhancing worker productivity. This forward-thinking approach ensures that goods are not just stored efficiently, but are also positioned for efficient retrieval. Over time, this can lead to significant savings in labor costs, as workers spend less time traveling within the warehouse. Additionally, by optimizing pick paths, the system can also reduce the wear and tear on material handling equipment, leading to longer equipment lifespans and reduced maintenance costs.

Zone-Based Storage

For warehouses that utilize zone-based storage, our Putaway Feature seamlessly integrates with this approach. It can suggest locations within designated zones, ensuring that items are stored in the right environment and are easily accessible for future operations. Zone-based storage is particularly beneficial for warehouses that handle a diverse range of products, each with its own storage requirements. For instance, perishable goods might be stored in a temperature-controlled zone, while electronics might be stored in a humidity-controlled zone. By supporting zone-based storage, our system ensures that each product is stored under optimal conditions, preserving its quality and ensuring it’s ready for dispatch when needed.

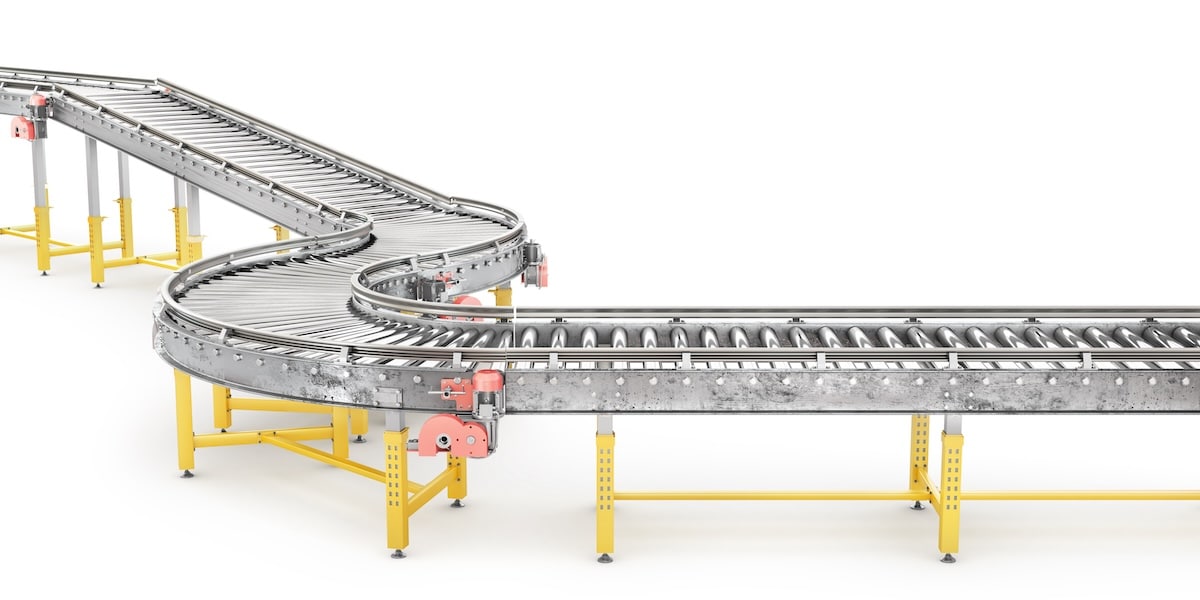

Automated Putaway Support

For warehouses leveraging automation, our system integrates seamlessly with automated storage and retrieval systems (AS/RS), WCS, robotic systems, and conveyor belts, ensuring that the putaway process is both fast and accurate. This integration is crucial for warehouses looking to achieve high levels of efficiency. By leveraging automation, warehouses can reduce the time and labor costs associated with putaway, leading to significant cost savings. Additionally, by integrating with automated systems, our Putaway Feature can ensure that goods are stored with a high degree of accuracy, reducing the risk of errors.

Scalability for Growth

As your business grows, so do your putaway needs. Our system is designed to scale with your operations, ensuring that whether you’re storing a hundred items or a million, the putaway process remains efficient. This scalability is crucial for businesses that anticipate future growth. By choosing a system that can scale, businesses can ensure that their putaway operations remain efficient, even as their inventory levels increase. Additionally, by choosing a scalable system, businesses can avoid the costs and disruptions associated with system upgrades or replacements.

Exception Handling

In the dynamic environment of a warehouse, exceptions are bound to occur. Our system offers robust exception handling features, allowing for quick resolution of issues, be it damaged goods, misplaced items, or storage discrepancies. These exceptions can be flagged in real-time, ensuring that corrective action is taken promptly. Additionally, by tracking exceptions, the system can provide insights into recurring issues, allowing managers to implement preventive measures.

User-Friendly Interface

Our Putaway Feature boasts a user-friendly interface, ensuring that whether it’s a seasoned warehouse worker or a new recruit, all can navigate and utilize the system with ease. This user-friendliness is not just about ease of use; it’s also about efficiency. By offering an intuitive interface, our system ensures that workers can perform putaway operations quickly, without the need for extensive training or reference materials. Additionally, by offering features like barcode scanning and voice commands, our system ensures that workers can perform putaway operations hands-free, further enhancing efficiency.

Still have questions? Contact ASC Software today to setup a call or demo Contact Us

Recent Blogs

Essential Manufacturing KPIs for Optimizing Performance

Reading time: 10 minutes In the realm of manufacturing, Key Performance Indicators (KPIs), also known as manufacturing KPIs, can make or …

The Cost of Automated Storage and Retrieval Systems

Reading time: 8 minutes Discover what automated storage and retrieval systems really cost and how they can pay off for your …

Reading time: 7 minutes Discover how conveyor systems revolutionize warehouse operations, optimizing efficiency and productivity. The Role of Conveyor Systems in …