What Is Warehouse Material Handling?

Warehouse material handling encompasses all activities involved in moving, storing, controlling, and protecting products throughout the warehouse environment. This critical operational component serves as the backbone of any effective supply chain, directly impacting everything from order fulfillment speed to overall operational costs. Whether you’re managing a small distribution center or overseeing a massive fulfillment operation, the principles of effective warehouse material handling remain consistent: to minimize unnecessary movement, maximize space utilization, and ensure product integrity while maintaining worker safety. For warehouse managers and logistics professionals, mastering material handling fundamentals provides a competitive advantage that can significantly boost operational efficiency.

Material handling influences nearly every aspect of warehouse operations, from receiving to shipping. When implemented correctly, effective material handling systems reduce labor costs, minimize product damage, optimize storage capacity, and increase throughput. The ripple effects extend beyond the warehouse walls, impacting customer satisfaction through faster order processing and fewer shipping errors. Additionally, well-designed material handling processes contribute significantly to worker safety by reducing physical strain and preventing accidents related to manual lifting or equipment operation.

Industry research consistently shows that inefficient material handling can account for up to 50% of warehouse operating costs, making it a prime target for operational improvements. With rising customer expectations for rapid order fulfillment and perfect accuracy, warehouse managers must continuously evaluate and enhance their material handling systems to remain competitive.

Smarter Warehouse Management Starts Here

ASCTrac WMS delivers real-time visibility, automated workflows, and seamless ERP integration for warehouses of every size.

Request a Demo

Essential Material Handling Equipment

The foundation of any efficient warehouse operation relies on selecting the right material handling equipment to match specific operational needs. Conveyors remain one of the most versatile and widely used systems, offering continuous movement of products between workstations while reducing manual handling. Modern conveyor systems range from gravity-powered rollers to sophisticated motorized belt systems with integrated sorting capabilities. Forklifts represent another cornerstone of material handling, with various types including counterbalance, reach trucks, and order pickers designed for specific warehouse applications. For smaller operations or areas with space constraints, pallet jacks provide an economical solution for moving palletized goods over short distances without the investment or training requirements of powered equipment.

The technological evolution of material handling continues with automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) gaining traction in warehouses of all sizes. These self-navigating vehicles can transport materials without human operators, following predetermined routes or using sensors to navigate dynamically. While requiring higher initial investment, these automated solutions deliver long-term benefits through labor savings, increased accuracy, and 24/7 operational capability. For specialized handling needs, equipment like vertical lift modules (VLMs), carousels, and pick-to-light systems offer storage density and picking efficiency improvements for smaller items.

Selecting the appropriate material handling equipment requires careful analysis of several factors including product characteristics, throughput requirements, storage constraints, and budget considerations. Product weight, dimensions, and fragility will influence equipment choices, as will the volume and velocity of goods moving through the facility. Warehouse ceiling height, aisle width, and floor conditions create physical constraints that may limit equipment options. Additionally, managers must consider equipment versatility, maintenance requirements, and potential for future integration with warehouse management systems when making investment decisions. The most successful operations typically employ a mix of equipment types to address varying handling requirements across different warehouse zones.

Equipment maintenance plays a crucial role in ensuring operational continuity and worker safety. Implementing a preventive maintenance schedule reduces unexpected downtime while extending equipment lifespan. This should include regular inspection of critical components, lubrication of moving parts, and prompt replacement of worn items before they lead to more significant failures. Staff training represents another essential aspect of equipment management, with operators requiring thorough instruction not only in basic operation but also in safety protocols and daily maintenance checks. Many facilities have found success with operator certification programs that ensure consistent operational standards across all shifts.

Common Material Handling Equipment Categories

- Storage Equipment: Includes pallet racks, shelving, mezzanines, and storage bins that maximize cubic space utilization

- Transport Equipment: Conveyors, forklifts, pallet jacks, carts, and automated vehicles that move products horizontally or vertically

- Positioning Equipment: Work tables, lift tables, and turntables that position materials for efficient handling

- Unitization Equipment: Pallets, containers, and stretch wrapping machines that consolidate items into manageable units

- Identification Equipment: Barcode scanners, RFID readers, and vision systems that track inventory movement

Optimizing Warehouse Layout for Efficient Material Handling

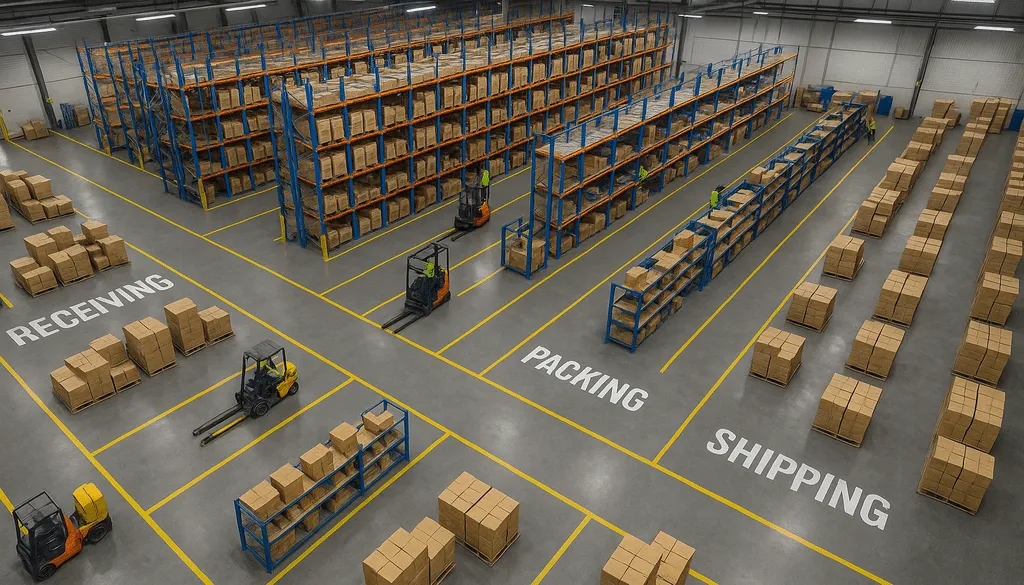

A strategically designed warehouse layout forms the foundation for efficient material handling operations. The physical arrangement of receiving areas, storage zones, picking stations, packing areas, and shipping docks directly impacts travel distance, labor utilization, and overall throughput capacity. Effective layouts minimize unnecessary movement by positioning high-velocity items near shipping areas and grouping complementary products to streamline order picking. According to industry studies, poor warehouse layouts can increase travel time by up to 60%, dramatically reducing productivity and increasing labor costs. Progressive warehouse managers recognize that layout optimization represents a continuous process rather than a one-time project, requiring regular evaluation as product mix, order profiles, and business requirements evolve.

Flow path analysis serves as a critical tool when designing or refining warehouse layouts. This technique tracks the movement of materials from receiving through shipping, identifying bottlenecks, redundant handling, and excessive travel distances. Most warehouses benefit from implementing either a U-shaped or straight-line flow configuration based on their specific requirements. U-shaped flows position receiving and shipping docks on the same side of the building, which conserves yard space and simplifies supervision, while straight-line flows move products sequentially from one end of the warehouse to the other, reducing congestion and crossover traffic. Either approach should incorporate principles like FIFO (First-In, First-Out) product rotation and strategic cross-aisles to enhance accessibility and picking efficiency.

Aisle configuration significantly impacts both space utilization and material handling equipment options. Traditional warehouse designs featured wide aisles (12+ feet) to accommodate counterbalance forklifts and enable two-way traffic. However, modern operations often implement narrow aisle configurations (8-10 feet) or very narrow aisle designs (5-7 feet) that increase storage density by 25-40% while requiring specialized equipment like reach trucks or turret trucks. The optimal aisle width balances storage capacity against accessibility needs, considering factors such as picking frequency, equipment turning radius, and throughput requirements. Forward-thinking warehouse managers also incorporate staging areas at strategic locations to prevent congestion during peak activity periods.

Integrating storage solutions with appropriate material handling equipment creates a cohesive system that maximizes efficiency. Vertical storage options like high-bay racking systems paired with order picker trucks or automated storage and retrieval systems (AS/RS) utilize overhead space effectively in facilities with sufficient ceiling height. For operations handling small parts or slow-moving inventory, carousels or vertical lift modules reduce floor space requirements while improving picking accuracy and ergonomics. Mezzanine installations create multi-level work areas that effectively double usable floor space for lightweight processing or storage applications. The most successful warehouse layouts maintain flexibility through modular design elements that can be reconfigured as operational needs change without major disruption to ongoing activities.

Layout Design Best Practices

- Analyze product movement data to identify high-velocity items deserving prime locations

- Implement clear product zoning based on size, velocity, or handling requirements

- Design adequate staging areas to prevent bottlenecks during peak periods

- Maintain straight traffic lanes with minimal intersections to reduce accidents

- Consider future growth requirements when establishing initial layout

- Create dedicated areas for value-added services like kitting or special packaging

Leveraging Warehouse Inventory Management Software

Warehouse inventory management software serves as the technological backbone of effective material handling operations, providing real-time visibility and control over inventory movement. These sophisticated systems track products from receipt through shipping while optimizing storage locations, directing picking activities, and maintaining accurate inventory counts. Modern warehouse management systems (WMS) integrate seamlessly with material handling equipment through barcode scanners, RFID readers, and voice picking technologies to eliminate paper-based processes and reduce error rates. Research indicates that implementing WMS solutions typically reduces labor costs by 15-20% while improving inventory accuracy to 99.5%+ through systematic verification procedures and elimination of manual data entry.

Advanced inventory management platforms enhance material handling efficiency through intelligent slotting capabilities that determine optimal product locations based on multiple variables. These systems analyze picking frequency, product dimensions, weight, storage requirements, and complementary item relationships to position inventory for minimal travel time and maximum space utilization. Dynamic slotting algorithms continuously refine product placement as sales patterns evolve, automatically adjusting locations to maintain optimal picking efficiency throughout seasonal fluctuations or promotional periods. The resulting improvements in labor productivity and order fulfillment speed create competitive advantages through reduced operating costs and enhanced customer satisfaction.

Warehouse execution systems represent the next evolution in inventory management software, bridging the gap between WMS platforms and material handling equipment through sophisticated orchestration capabilities. These systems optimize workflows in real-time, balancing labor resources against equipment capacity to maintain continuous product flow. When integrated with automated material handling equipment like conveyors, sorters, or robotic picking systems, execution software synchronizes mechanical movements with digital instructions to create seamless operations. The result is significantly increased throughput capacity and the ability to handle complex order profiles with minimal human intervention.

Mobile technology continues transforming warehouse operations through wireless devices that bring inventory management capabilities directly to the point of activity. Handheld computers, wearable scanners, and tablet devices equipped with warehouse applications provide real-time visibility while enabling instantaneous decision-making. These mobile tools eliminate non-productive travel time between workstations and computer terminals, allowing workers to remain in their operational areas while accessing system information. For material handling specifically, mobile devices facilitate immediate capture of product movements, error identification, and exception handling, creating a feedback loop that enhances system accuracy. As warehouse technology continues evolving, expect to see increased integration between inventory management software and emerging technologies like artificial intelligence, predictive analytics, and augmented reality to further optimize material handling processes.

Key Features of Effective Inventory Management Software

- Real-time inventory tracking and location management

- Directed put-away and picking functionality

- Labor management and performance tracking

- Integration capabilities with material handling automation

- Analytical reporting for continuous improvement

- Exception management alerts for immediate problem resolution

- Mobile accessibility for operational flexibility

Tips and Best Practices for Safe and Productive Material Handling

Comprehensive staff training forms the cornerstone of safe and efficient material handling operations. Beyond basic equipment operation, effective training programs should address proper lifting techniques, load stability principles, equipment inspection procedures, and hazard recognition. Ergonomic practices deserve special emphasis, including teaching workers to maintain neutral postures, avoid overreaching, and use mechanical aids whenever possible to reduce physical strain. Leading warehouse operations implement hands-on training that combines classroom instruction with supervised practice in actual work environments. Regular refresher sessions and safety certifications help reinforce proper techniques while ensuring compliance with OSHA regulations and industry standards. The investment in thorough training typically returns substantial dividends through reduced injuries, decreased workers’ compensation claims, and improved operational efficiency.

Standardized operating procedures (SOPs) provide the framework for consistent material handling practices across all shifts and operational areas. These documented processes should address every aspect of material movement, from receiving protocols to storage practices and order fulfillment workflows. Effective SOPs include detailed step-by-step instructions, safety precautions, required equipment, and quality control checkpoints for each process. The development process should involve input from experienced floor personnel who understand practical operational challenges. Once established, SOPs require regular review and updates to incorporate process improvements and technological advancements. Many successful warehouse operations utilize visual management techniques like color coding, workflow diagrams, and quick-reference guides to reinforce procedural compliance throughout the facility.

Preventive maintenance schedules represent another critical best practice for material handling success. Rather than waiting for equipment failures that disrupt operations, proactive maintenance programs identify and address potential issues before they cause downtime. These programs should include daily operator inspections, scheduled service intervals based on usage hours or calendar time, and comprehensive documentation of all maintenance activities. Many warehouse operations implement computerized maintenance management systems (CMMS) that track equipment history, schedule upcoming service requirements, and maintain parts inventories. This systematic approach extends equipment lifespan, reduces repair costs, and minimizes operational disruptions while ensuring consistent performance and safety compliance.

Continuous improvement methodologies like Lean and Six Sigma provide structured approaches for identifying and eliminating inefficiencies in material handling processes. These systems employ tools such as value stream mapping, root cause analysis, and statistical process control to target waste reduction and quality improvements. Regular performance measurement through key metrics like order accuracy, cycle time, labor productivity, and equipment utilization creates accountability and highlights improvement opportunities. Leading warehouse operations establish cross-functional improvement teams that regularly analyze operational data, identify bottlenecks, and implement targeted solutions. This ongoing refinement process ensures that material handling systems evolve to meet changing business requirements while maintaining peak efficiency.

Material Handling Safety Checklist

- Implement comprehensive pre-shift equipment inspections

- Enforce clear traffic patterns with designated pedestrian walkways

- Maintain proper lighting in all operational areas

- Require appropriate personal protective equipment (PPE)

- Establish maximum load ratings for all storage equipment

- Conduct regular safety audits and promptly address identified issues

- Encourage near-miss reporting to prevent potential accidents

Conclusion

Effective warehouse material handling represents the critical foundation that supports operational excellence in today’s competitive logistics landscape. By implementing the right combination of equipment, layout design, inventory management software, and operational best practices, warehouse managers can dramatically improve productivity while reducing costs and enhancing safety. The interconnected nature of these elements means that improvements in one area often yield benefits across the entire operation. As customer expectations continue rising for faster delivery and perfect order accuracy, warehouse material handling capabilities increasingly determine which companies thrive and which struggle to compete.

The future of warehouse material handling will continue evolving through technological advancements and innovative approaches to age-old challenges. Automation technologies including robotics, autonomous vehicles, and artificial intelligence are becoming increasingly accessible to operations of all sizes, offering new opportunities to enhance material flow and reduce labor dependencies. However, even with these technological advances, the fundamental principles of efficient movement, proper equipment selection, optimized layouts, and systematic processes remain essential for success. Organizations that commit to continuous improvement in their material handling practices position themselves for sustained competitive advantage in an increasingly demanding marketplace.

Remember that implementing effective material handling systems requires both technical understanding and practical experience. Start with thorough analysis of your current operations, identify the most significant bottlenecks and safety concerns, and develop prioritized improvement plans that address immediate needs while building toward long-term objectives. Involve frontline staff in both the planning and implementation processes to gain valuable operational insights and build organizational buy-in. By approaching warehouse material handling as a comprehensive system rather than isolated components, you’ll create integrated solutions that deliver sustainable performance improvements across your entire operation.

Frequently Asked Questions (FAQ)

What is the most important factor in effective warehouse material handling?

The most important factor in effective warehouse material handling is the integration of the right equipment, optimized warehouse layout, and robust operational processes. Proper training of staff and the use of warehouse inventory management software help ensure accuracy, safety, and efficiency. By prioritizing workflow design, equipment selection, and real-time inventory tracking, warehouses can minimize errors, reduce downtime, and improve overall productivity. Continuous evaluation and process improvements are also key to adapting material handling practices as operational needs evolve.

How do I determine which material handling equipment is right for my warehouse?

Determining the right material handling equipment requires analyzing several factors including product characteristics (size, weight, fragility), throughput requirements, storage constraints, and budget considerations. Start by documenting your specific operational needs and current pain points. Consider the full lifecycle costs of equipment, including purchase, maintenance, energy consumption, and operator training. Many operations benefit from a phased implementation approach, beginning with essential equipment and adding specialized solutions as volumes increase. Consulting with material handling specialists and visiting similar operations can provide valuable insights before making significant investments.

What are the most common mistakes in warehouse material handling?

The most common mistakes include inadequate staff training, poor equipment maintenance, inefficient warehouse layouts, and failure to implement proper inventory management systems. Many operations also struggle with improper storage methods that waste space or create safety hazards, excessive manual handling that increases labor costs and injury risks, and insufficient process documentation leading to inconsistent practices between shifts. Reactive rather than preventive approaches to equipment maintenance and resistance to adopting new technologies also frequently limit operational effectiveness and efficiency.

How can I improve material handling safety in my warehouse?

Improving material handling safety requires a comprehensive approach that combines training, equipment maintenance, proper procedures, and ongoing vigilance. Start by implementing thorough safety training for all staff covering equipment operation, lifting techniques, hazard recognition, and emergency procedures. Establish clear traffic patterns with dedicated pedestrian walkways and enforce speed limits for powered equipment. Conduct regular equipment inspections and maintain preventive maintenance schedules. Create a safety committee with representation from all departments to identify potential hazards and recommend improvements. Most importantly, develop a culture where safety is prioritized over speed, and employees feel empowered to report unsafe conditions without fear of repercussions.

How do I measure the effectiveness of my warehouse material handling system?

Measuring effectiveness requires tracking key performance indicators (KPIs) that align with your operational objectives. Essential metrics include order fulfillment accuracy, picking productivity (lines per hour), equipment utilization rates, storage density (cubic space utilization), inventory accuracy, and labor efficiency. Safety metrics like recordable incidents, near misses, and lost time accidents provide critical insights into operational risks. More advanced operations also track cost per order, perfect order percentage, and dock-to-stock time. Establish baseline measurements before implementing changes, then regularly monitor progress toward established targets. Many warehouse management systems provide built-in reporting capabilities for these metrics, enabling data-driven decision-making for continuous improvement.