In today’s rapidly evolving manufacturing industry, it is crucial to have a clear understanding of shop floor control systems. These systems play a vital role in driving productivity, efficiency, and quality within a manufacturing facility. By effectively managing and controlling all operations on the shop floor, these systems ensure smooth production processes and facilitate timely decision-making.

Understanding the Basics of Shop Floor Control Systems

Shop floor control systems are designed to coordinate and monitor the various activities that occur on the shop floor. They provide real-time visibility into key manufacturing processes and help streamline operations, from material handling and production scheduling to inventory management and quality control.

One of the primary components of shop floor control systems is the work order management module. This module is responsible for capturing and organizing all relevant information about each work order, such as production requirements, due dates, and resource allocations. It enables manufacturers to prioritize and schedule tasks effectively, ensuring that production targets are met.

Another critical component of shop floor control systems is the machine monitoring module. This module tracks the performance of machines and equipment on the shop floor in real-time. It provides insights into machine utilization, downtime, and potential bottlenecks, allowing operators to take corrective actions promptly. By minimizing machine idle time and maximizing uptime, manufacturers can optimize production efficiency and minimize costs.

Key Components of Shop Floor Control Systems

Aside from work order management and machine monitoring, shop floor control systems typically include several other important components:

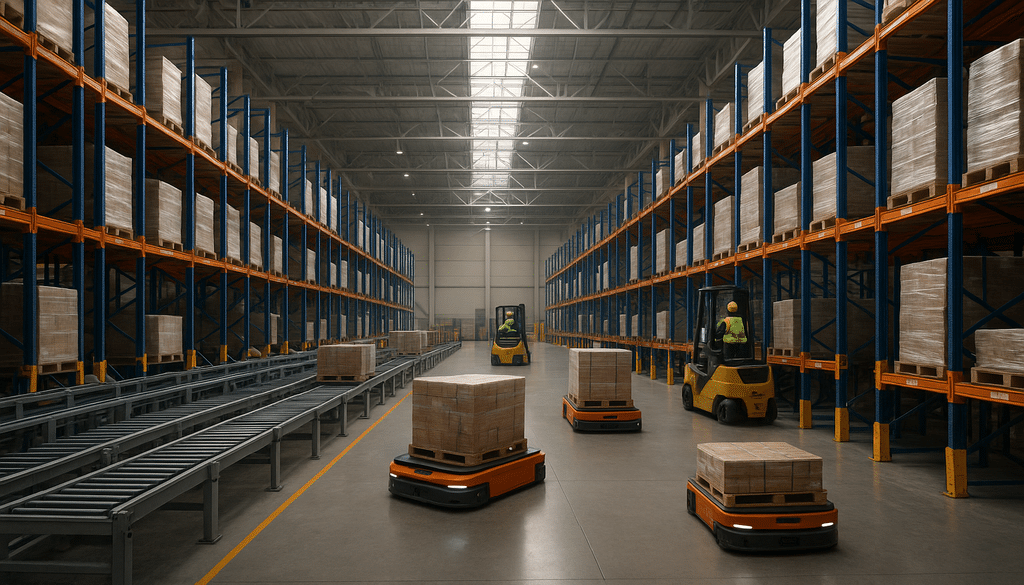

- Material tracking: This component ensures accurate tracking and tracing of materials throughout the production process, enabling manufacturers to maintain inventory levels and prevent stockouts or excess stock.

- Labor management: This module helps track and manage labor resources, ensuring efficient allocation and utilization of human capital. It facilitates labor scheduling, time tracking, and performance monitoring.

- Quality control: Shop floor control systems incorporate quality control features, such as inspection checklists and non-conformance reporting, to ensure that products meet the required standards and specifications.

- Reporting and analytics: These systems generate comprehensive reports and analytics, providing valuable insights into production performance, resource utilization, and overall efficiency. This information aids decision-making and continuous improvement initiatives.

The Role of Shop Floor Control in Manufacturing

Shop floor control systems play a critical role in manufacturing by improving operational efficiency, optimizing resource utilization, and enhancing overall product quality. They enable manufacturers to:

- Minimize production lead times by streamlining processes and eliminating bottlenecks.

- Reduce costs by efficiently managing resources, minimizing downtime, and eliminating waste.

- Ensure on-time delivery by accurate work order scheduling and real-time monitoring of production progress.

- Enhance product quality through effective quality control measures and real-time problem identification.

- Increase customer satisfaction by meeting delivery commitments and consistently delivering high-quality products.

The Significance of Shop Floor Control Systems

As manufacturing processes become increasingly complex and competitive, the importance of efficient shop floor control systems cannot be overstated. These systems have a direct impact on the overall performance and success of manufacturing operations.

Enhancing Efficiency with Shop Floor Control

Efficiency is a critical aspect of any manufacturing facility. Shop floor control systems improve operational efficiency by eliminating manual processes, automating data collection, and enabling real-time monitoring. By reducing human errors and inefficiencies, these systems enable manufacturers to achieve higher productivity levels and greater cost savings.

Moreover, shop floor control systems provide valuable insights into shop floor operations, allowing manufacturers to identify areas for improvement and implement corrective actions. By continuously analyzing data and metrics, manufacturers can optimize processes, enhance resource utilization, and achieve higher levels of efficiency throughout the production cycle.

Quality Control and Shop Floor Systems

Ensuring product quality is paramount in manufacturing. Shop floor control systems incorporate robust quality control features that enable manufacturers to monitor and maintain consistent product quality. By implementing standardized procedures, conducting inspections, and capturing relevant quality data, manufacturers can identify and address quality issues promptly.

Shop floor control systems also enable manufacturers to trace materials, track production inputs, and implement effective quality control measures at each stage of the production process. This level of control and visibility helps prevent defects, reduce rework and scrap, and ultimately deliver products that meet or exceed customer expectations.

The Evolution of Shop Floor Control Systems

Over the years, shop floor control systems have undergone significant transformations. From manual paper-based systems to highly automated and interconnected solutions, these systems have evolved to keep pace with advancements in technology and changing manufacturing requirements.

From Manual to Automated Systems

Historically, shop floor control systems relied on manual data collection and paper-based documentation. This approach was time-consuming, error-prone, and lacked real-time visibility. However, with the advent of computers and automation technologies, manufacturers began adopting more sophisticated systems.

Today, modern shop floor control systems leverage automation, connectivity, and data analytics capabilities. They integrate seamlessly with other enterprise resource planning (ERP) and manufacturing execution systems (MES), providing a comprehensive view of the entire manufacturing operation. Real-time data feeds and automated workflows enable efficient decision-making and enhance overall operational control.

The Impact of Technology on Shop Floor Control

The widespread adoption of technology has revolutionized shop floor control systems. The following technological advancements have significantly impacted these systems:

- Internet of Things (IoT): IoT technology has enabled the integration of various sensors and devices on the shop floor. These devices collect real-time data, monitor machine performance, and enable predictive maintenance, contributing to higher equipment uptime and improved productivity.

- Artificial Intelligence (AI): AI algorithms analyze vast amounts of shop floor data, enabling proactive decision-making and predictive analytics. AI-powered shop floor control systems can optimize production schedules, detect anomalies, and identify potential improvement opportunities without human intervention.

- Cloud computing: Cloud-based shop floor control systems offer scalability, mobility, and accessibility. Manufacturers can access crucial data and system functionality remotely, enabling seamless collaboration across teams and locations.

Implementing a Shop Floor Control System

Implementing a shop floor control system can be a daunting task, but it is essential for manufacturers looking to stay competitive in today’s dynamic marketplace. By following a structured approach, manufacturers can successfully integrate and leverage these systems in their operations.

Steps to Integrate a Shop Floor Control System

When implementing a shop floor control system, manufacturers should consider the following steps:

- Assess operational requirements: Understand the specific needs and goals of your manufacturing facility. Define the key functionalities desired from a shop floor control system and establish measurable success criteria.

- Choose the right system: Conduct thorough research and evaluation of available shop floor control systems. Consider factors such as scalability, compatibility with existing infrastructure, ease of integration, and user-friendliness.

- Plan for implementation: Develop a comprehensive implementation plan that includes milestones, timelines, resource allocation, and training requirements. Engage key stakeholders and communicate the plan clearly to ensure smooth execution.

- Test and validate: Before fully deploying the system, conduct rigorous testing to ensure compatibility, accuracy, and reliability. Validate system performance against predefined metrics and address any identified issues.

- Train employees: Provide comprehensive training to all employees who will interact with the shop floor control system. Ensure that they understand the system’s capabilities, functionalities, and their roles and responsibilities in using it effectively.

- Monitor and continuously improve: Regularly monitor the system’s performance and gather feedback from users. Use analytics and reporting features to identify areas for improvement, address inefficiencies, and drive continuous optimization.

Overcoming Challenges in System Implementation

Implementing a shop floor control system may present several challenges. However, by addressing these challenges proactively, manufacturers can ensure a successful implementation:

- Resistance to change: Employees may resist transitioning from manual to automated systems. Address this by communicating the benefits of the new system, providing adequate training, and involving employees in the decision-making process.

- Data collection and integration: Integrating the shop floor control system with existing systems and collecting accurate and timely data can be challenging. Invest in robust connectivity solutions, ensure data integrity, and establish data validation processes.

- Cultural alignment: Aligning the shop floor control system with the organization’s culture and processes is crucial. Involve key stakeholders from the outset and ensure that the system aligns with existing workflows.

- Vendor selection: Choosing the right vendor for the shop floor control system is vital. Evaluate vendors based on their industry experience, track record, customer support, and the ability to align with your specific requirements.

Future Trends in Shop Floor Control Systems

The future of shop floor control systems holds immense potential, driven by advancements in technology and evolving manufacturing needs. Two key trends are likely to shape the future of these systems:

The Role of AI and IoT in Shop Floor Control

As AI capabilities continue to advance, shop floor control systems will increasingly leverage AI algorithms to optimize decision-making, predict maintenance needs, and drive autonomous control. AI-powered systems will enhance real-time monitoring, enable predictive analytics, and improve overall operational efficiency.

Moreover, the integration of IoT technology will enable shop floor control systems to leverage the vast amounts of data generated by interconnected devices and sensors. This will enhance visibility and control, enable efficient resource allocation, and support data-driven decision-making throughout the production process.

Predictions for Future Shop Floor Control Developments

In the coming years, shop floor control systems are likely to evolve in the following ways:

- Greater connectivity: Shop floor control systems will become even more interconnected with other systems, such as ERP and MES, facilitating seamless data exchange and optimizing operational control.

- Real-time performance monitoring: Advancements in IoT and sensor technologies will enable real-time monitoring of machine performance, energy consumption, and overall production efficiency.

- Advanced analytics and machine learning: Shop floor control systems will leverage advanced analytics and machine learning algorithms to derive insights, enable predictive maintenance, and enhance decision-making capabilities.

- Integration of virtual and augmented reality: Virtual and augmented reality technologies will play a more prominent role in shop floor control systems. These technologies will enable remote collaboration, immersive training, and virtual simulations of production processes.

In conclusion, understanding the definition and importance of shop floor control systems is crucial for manufacturers striving to improve productivity and efficiency. These systems not only optimize operational control but also play a vital role in achieving higher product quality and customer satisfaction. By embracing advancements in technology, intelligently implementing these systems, and keeping an eye on future trends, manufacturers can stay ahead in a rapidly changing manufacturing landscape.