In today’s competitive manufacturing landscape, optimizing shop floor control is crucial for achieving operational efficiency and driving business success. By effectively managing and controlling manufacturing processes, companies can improve productivity, reduce costs, and ensure timely delivery of high-quality products. This article explores the concept of shop floor control, the role of technology in optimizing operations, strategies for overcoming challenges, and measuring success through key performance indicators.

Understanding Shop Floor Control

Definition and Importance of Shop Floor Control

Shop floor control refers to the system and processes implemented to manage and control the production activities on the shop floor. It involves overseeing all aspects of production, from scheduling and resource allocation to monitoring and measuring performance. Shop floor control plays a critical role in driving operational efficiency, ensuring on-time delivery, and meeting customer demands.

Efficient shop floor control is essential for manufacturing companies to streamline their production processes and maximize productivity. By implementing effective shop floor control systems, businesses can optimize resource utilization, minimize waste, and enhance overall operational performance. This results in cost savings, improved customer satisfaction, and a competitive edge in the market.

Key Components of Shop Floor Control

Effective shop floor control requires the integration of various components. These include:

- Production Planning: Developing efficient production schedules based on customer orders, resource availability, and production capacity.

- Work Order Management: Assigning and tracking work orders to ensure smooth flow of production and timely completion.

- Inventory Management: Monitoring and controlling inventory levels to avoid stockouts and reduce carrying costs.

- Machine Monitoring: Collecting real-time data on machine performance to detect issues, optimize utilization, and minimize downtime.

- Quality Control: Implementing quality standards and processes to ensure product consistency and customer satisfaction.

Furthermore, shop floor control systems often incorporate advanced technologies such as Internet of Things (IoT) devices, artificial intelligence, and data analytics to enhance decision-making and improve operational efficiency. These technologies enable real-time monitoring of production processes, predictive maintenance of equipment, and data-driven insights for continuous process improvement.

The Role of Technology in Shop Floor Control

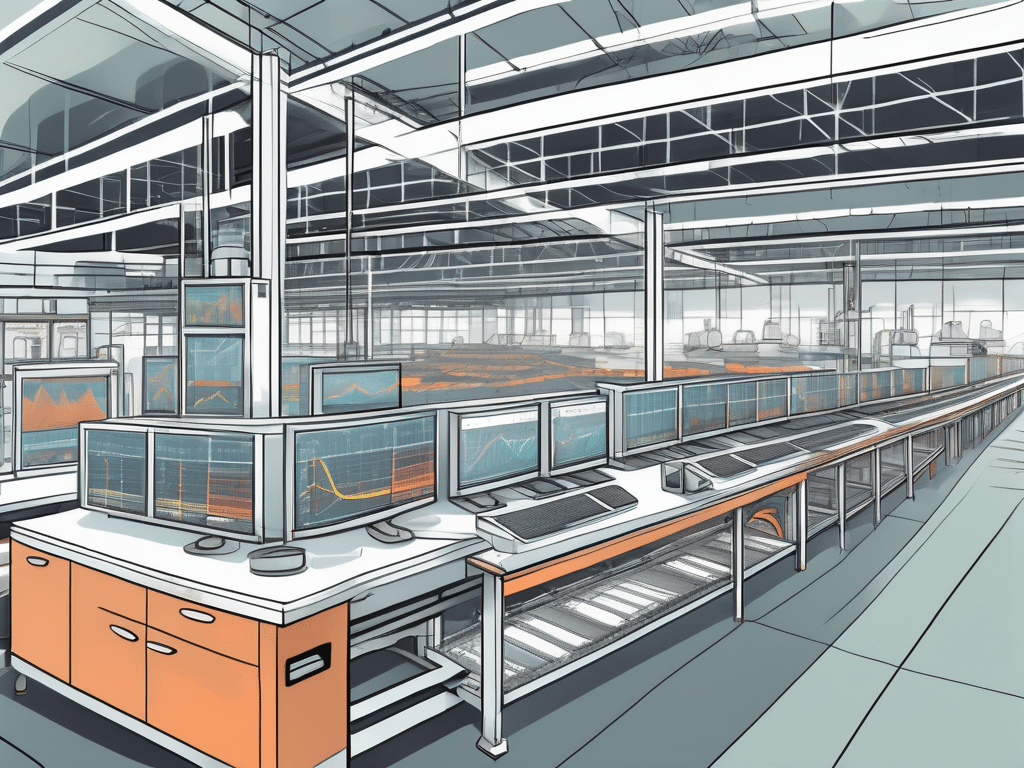

Modern Software Solutions for Shop Floor Control

Advancements in technology have revolutionized shop floor control, enabling manufacturers to streamline operations and enhance efficiency. Modern software solutions, such as Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems, provide real-time visibility into production processes, automate data collection, and facilitate effective decision-making. These tools enable manufacturers to optimize resource utilization, track performance metrics, and improve overall operational efficiency.

Moreover, the integration of Internet of Things (IoT) devices in shop floor control systems has further transformed manufacturing processes. IoT sensors embedded in machinery and equipment collect real-time data on performance, maintenance needs, and energy consumption. This data is then analyzed to identify patterns, predict maintenance requirements, and optimize production schedules. By leveraging IoT technology, manufacturers can achieve higher levels of automation, reduce downtime, and enhance overall productivity.

Additionally, the implementation of cloud-based shop floor control solutions has revolutionized the way manufacturers manage their operations. Cloud computing offers scalability, flexibility, and accessibility, allowing manufacturers to access critical production data from anywhere at any time. This remote accessibility enables real-time monitoring of production processes, collaboration among teams, and quick decision-making based on accurate information. Cloud-based shop floor control systems not only improve operational efficiency but also enhance data security and disaster recovery capabilities.

The Impact of Automation and AI

The integration of automation and artificial intelligence (AI) technologies further enhances shop floor control. Automated machines and robotics streamline production, reduce human errors, and increase throughput. AI-driven analytics and predictive maintenance algorithms help identify potential bottlenecks, optimize scheduling, and proactively address issues before they impact production. These technologies significantly improve efficiency, reduce costs, and ensure optimal resource allocation.

Strategies for Optimizing Shop Floor Control

Streamlining Production Processes

To optimize shop floor control, it is vital to streamline production processes. This involves eliminating unnecessary steps, reducing setup/changeover times, and ensuring seamless flow between workstations. Implementing lean manufacturing principles, such as 5S and Kanban, promotes efficiency and minimizes waste. Additionally, adopting methodologies like Six Sigma and Total Productive Maintenance (TPM) helps identify and eliminate process inefficiencies, leading to improved productivity and higher-quality output.

One key aspect of streamlining production processes is the concept of value stream mapping. This technique allows manufacturers to visualize the entire production process from start to finish, identifying areas of improvement and optimizing the flow of materials and information. By analyzing value streams, companies can eliminate bottlenecks, reduce lead times, and enhance overall operational efficiency.

Enhancing Real-Time Visibility and Control

Real-time visibility and control are crucial for effective shop floor management. Implementing IoT-enabled sensors and connected devices provides real-time data on machine performance, process parameters, and inventory levels. Integrating this data with shop floor control systems enables proactive decision-making, facilitates predictive analytics, and enhances overall production efficiency. By having access to accurate and timely information, manufacturers can address issues promptly, optimize resource allocation, and ensure uninterrupted production.

Furthermore, the implementation of a Manufacturing Execution System (MES) can greatly enhance real-time visibility and control on the shop floor. MES software allows for the monitoring and tracking of production processes in real time, providing detailed insights into machine utilization, production rates, and quality metrics. By leveraging MES technology, manufacturers can improve production planning, optimize scheduling, and achieve greater operational transparency.

Overcoming Challenges in Shop Floor Control

Dealing with Common Obstacles

Implementing and optimizing shop floor control may present several challenges. These can include resistance to change, lack of employee buy-in, and outdated legacy systems. Overcoming these obstacles requires effective change management strategies, comprehensive training programs, and thorough system evaluations and upgrades. Engaging employees, fostering a culture of continuous improvement, and leveraging technology advancements can help mitigate these challenges and optimize shop floor control.

One common challenge in shop floor control is the integration of new technologies with existing systems. This can lead to compatibility issues, data discrepancies, and disruptions in production processes. To address this, companies must conduct thorough compatibility tests, provide adequate training on new technologies, and establish clear protocols for system integration.

Another obstacle that organizations face is the lack of real-time visibility and data accuracy on the shop floor. This can result in delays, errors, and inefficiencies in production. Implementing IoT devices, RFID technology, and real-time monitoring systems can enhance visibility, improve data accuracy, and enable proactive decision-making on the shop floor.

Tips for Effective Problem-Solving

When facing problems in shop floor control, effective problem-solving techniques can make a significant difference. Encouraging collaboration among cross-functional teams, utilizing root cause analysis methodologies, and implementing corrective actions based on data-driven insights are key strategies. Regular performance reviews, continuous monitoring of key metrics, and timely intervention ensure proactive problem-solving and continuous improvement.

Furthermore, fostering a culture of innovation and experimentation can empower employees to identify and address challenges in shop floor control. Encouraging feedback, rewarding innovative solutions, and providing resources for experimentation create an environment where continuous problem-solving and process improvement thrive.

Measuring the Success of Your Shop Floor Control

Key Performance Indicators (KPIs) for Shop Floor Control

Measuring and monitoring key performance indicators (KPIs) is essential for evaluating the effectiveness of shop floor control. By tracking these KPIs, manufacturers can gain valuable insights into their operations and make informed decisions to drive improvement. Some important KPIs to consider include:

- Overall Equipment Efficiency (OEE): Calculating the efficiency of machine utilization, availability, and overall performance provides a comprehensive view of how effectively resources are being utilized on the shop floor.

- Production Cycle Time: Tracking the time taken for a product to go through the entire production process helps identify bottlenecks and streamline operations for improved efficiency.

- Defect Rate: Monitoring the percentage of products that do not meet quality standards allows manufacturers to identify areas for improvement in their production processes and reduce waste.

- On-Time Delivery: Measuring the ability to deliver products to customers within the agreed-upon timeframe is crucial for maintaining customer satisfaction and building strong relationships.

- Inventory Turnover: Assessing the rate at which inventory is sold and replaced over a specific period helps optimize inventory management and reduce carrying costs.

Continuous Improvement in Manufacturing Operations

Optimizing shop floor control is an ongoing process that requires continuous improvement efforts. Regularly reviewing performance metrics, analyzing data, and identifying areas for improvement allow manufacturers to continually enhance operational efficiency, reduce costs, and deliver superior products.

One effective strategy for continuous improvement is implementing lean manufacturing principles. By eliminating waste, streamlining processes, and empowering employees to contribute to improvement initiatives, organizations can achieve significant gains in productivity and quality.

Another important aspect of continuous improvement is investing in technology. Adopting advanced manufacturing technologies, such as automation and data analytics, can provide real-time visibility into shop floor operations, enabling faster decision-making and proactive problem-solving.

Overcoming challenges is also a critical part of the continuous improvement journey. Manufacturers may face obstacles such as resistance to change, lack of employee engagement, or limited resources. By fostering a culture of collaboration, providing training and development opportunities, and allocating resources strategically, organizations can overcome these challenges and drive sustainable improvement.

By embracing a culture of continuous improvement, organizations can stay competitive in the ever-evolving manufacturing landscape. By prioritizing shop floor control optimization and implementing effective strategies, manufacturers can achieve operational excellence, enhance customer satisfaction, and drive long-term business success.

Remember, the journey towards operational excellence is an ongoing one. By consistently measuring success through KPIs and striving for continuous improvement, manufacturers can unlock their full potential and thrive in today’s dynamic marketplace.