Radio Frequency Identification (RFID) technology has become an indispensable tool for modern manufacturing, offering a wide range of benefits, including improved inventory management, enhanced asset tracking, and increased operational efficiency.

This comprehensive guide will provide you with everything you need to know about RFID in manufacturing, from getting started to best practices and more. By the end of this article, you’ll be well-equipped to harness the full potential of RFID technology in your manufacturing operations.

Understanding RFID Technology and RFID Tags in Manufacturing

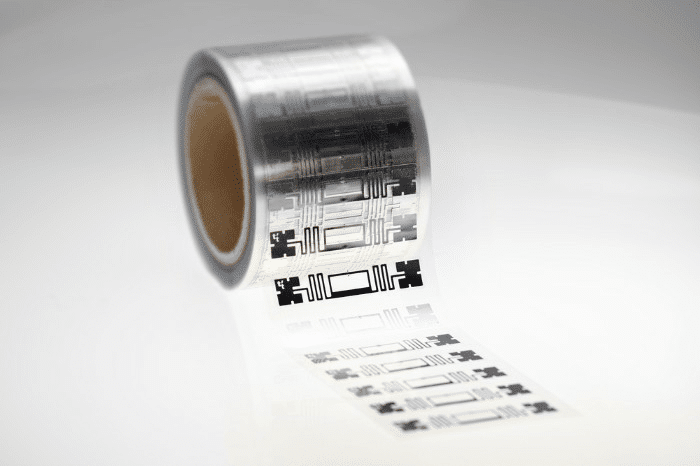

RFID technology uses radio waves to transmit data stored on RFID tags, which are small devices containing an integrated circuit and an antenna. These tags come in various forms, such as RFID inlays, RFID labels, and hard tags, and operate at different frequencies, including low, high, and ultra-high frequency. There are several types of RFID tags, including passive RFID tags, active RFID tags, and semi-passive RFID tags, each with its own advantages and suited for different applications.

RFID tags can be attached to a wide range of items, including raw materials, components, and finished products, enabling real-time tracking and identification. This significantly reduces manual labor, errors, and delays in the manufacturing process. RFID tags in manufacturing have become an essential aspect of modern warehouse management, allowing companies to maintain accurate inventories, increase production efficiency, and reduce overall costs.

RFID systems allow for the simultaneous reading of multiple tags, streamlining processes and reducing labor requirements. Furthermore, RFID printers enable the creation of human-readable information on the tags, enhancing data collection capabilities. Overall, RFID-based systems offer a more efficient method of data collection compared to alternatives like barcodes.

Types of RFID Systems: Active vs. Passive

As we mentioned, there are two primary types of RFID systems used in manufacturing environments: passive and active. Active tags (active RFID tags) contain their own internal source of power, such as a battery, and emit a continuous signal, enabling real-time tracking over a considerable distance. Active RFID systems generally have a longer read range and can conserve battery life by entering a sleep mode when not in use.

On the other hand, passive RFID tags, or passive tags, do not have a built-in power source and instead, require the energy emitted by an RFID sensor to transmit data. Passive RFID asset tracking is generally more cost-effective and energy-efficient, making it the preferred choice for most manufacturing applications.

Both active and passive tags are suited for different scenarios, depending on factors such as read range, durability, and compatibility with existing systems. For example, some manufacturing environments may require a combination of passive and active tags to achieve the desired level of efficiency and accuracy.

Benefits of Passive RFID Tracking Systems in Manufacturing

A passive RFID tracking system offers a range of benefits for manufacturing environments, including:

- Improved inventory management: Accurate, real-time tracking of assets and inventory levels using passive RFID tags and RFID readers helps prevent stock-outs, overstocking, and waste, optimizing the supply chain.

- Enhanced asset tracking: RFID technology allows warehouse professionals to quickly locate and identify valuable assets, such as medical equipment and physical assets, streamlining processes such as maintenance, quality control, and audit.

- Increased production efficiency: Automated data collection and communication between RFID systems and other manufacturing technologies result in faster and more accurate decision-making, reducing downtime and increasing output.

- Greater accuracy and reduced errors: RFID systems minimize human intervention, which reduces the likelihood of errors and improves the overall quality of operations.

Implementing RFID Controls in Manufacturing

Successfully implementing RFID controls in a manufacturing environment requires careful planning and consideration. Warehouse professionals should follow these steps to ensure a smooth transition to an RFID-enabled operation:

- Evaluate current processes and identify areas for improvement.

- Select the appropriate RFID technology based on specific needs.

- Develop a comprehensive RFID implementation plan, including timelines, resources, and budget.

- Train employees on how to use RFID systems and ensure they understand the benefits of the technology.

- Test the RFID system in a controlled environment to identify and resolve any issues before full-scale deployment.

- Continuously monitor and evaluate the performance of the RFID system, making adjustments as necessary to optimize its effectiveness.

Ready to Revolutionize Your Manufacturing Operations?

Discover the full potential of RFID technology for your manufacturing processes with ASC Software. Enhance efficiency, reduce errors, and gain unparalleled visibility into every aspect of your production.

Optimize ManufacturingA Step-by-Step Guide to Getting Started with RFID in Manufacturing

To implement RFID technology in your manufacturing operations, follow these steps:

- Assess your requirements: Determine the specific goals and objectives you hope to achieve by implementing RFID technology. This may include improving inventory accuracy, streamlining asset tracking, or enhancing overall operational efficiency.

- Choose the right RFID tags and readers: Based on your requirements, select the appropriate type of RFID tags (passive, active, or semi-passive) and RFID readers that will best suit your needs. Consider factors such as read range, durability, and compatibility with existing systems.

- Select RFID software: Choose an RFID software solution that will enable you to manage your RFID system effectively. This may include asset tracking software, inventory management software, or a comprehensive warehouse management system, such as ASC Software’s ASCTrac® WMS.

- Design your RFID infrastructure: Develop a layout for your RFID system, including the placement of RFID readers, antennas, and printers. Ensure that the design takes into account potential interference from other equipment or harsh environments.

- Train your staff: Provide training to your employees on the proper use of RFID technology and equipment, emphasizing the benefits and importance of accurate data collection.

- Test your RFID system: Before deploying your RFID system on a large scale, conduct thorough testing to identify and resolve any potential issues or inefficiencies.

- Monitor and optimize: Regularly review the performance of your RFID system and make adjustments as needed to maximize its effectiveness and return on investment.

Best Practices for RFID Implementation and Management

Following best practices for RFID implementation and management can help ensure the success of your RFID system:

- Use high-quality RFID tags and readers to ensure reliability and performance.

- Regularly inspect and maintain your RFID equipment, including readers, antennas, and printers, to prevent downtime and ensure optimal performance.

- Continuously monitor and analyze data collected by your RFID system to identify trends, patterns, and areas for improvement.

- Integrate your RFID system with other manufacturing technologies, such as IoT devices, AI, and big data analytics, to create a more interconnected and intelligent manufacturing environment.

- Implement robust security measures, including encryption and authentication, to protect sensitive data and prevent unauthorized access to tagged items.

Real-World Examples of RFID in Manufacturing

Countless manufacturers have successfully implemented RFID technology in their operations. Here are some real-world examples:

- Automotive industry: Car manufacturers use RFID to track and manage parts and assemblies throughout the production process, ensuring timely delivery and reducing errors.

- Pharmaceutical industry: RFID is employed for inventory management, tracking drug expiration dates, and preventing counterfeit products from entering the supply chain.

- Aerospace industry: RFID technology helps track and manage high-value components, monitor maintenance schedules, and improve overall asset management.

The Future of RFID in Manufacturing

The future of RFID in manufacturing is promising, as advancements in technology continue to drive improvements in efficiency, accuracy, and cost-effectiveness. Some trends and developments to watch for include:

- Integration with other emerging technologies: As the Internet of Things (IoT), artificial intelligence (AI), and blockchain technology become more prevalent in manufacturing, RFID systems will likely be integrated with these technologies to create even more efficient, connected, and intelligent manufacturing environments.

- Smaller, more advanced RFID tags: As RFID tag manufacturing technology improves, tags are expected to become smaller and more advanced, allowing for more diverse applications and improved performance.

- Enhanced security features: As concerns about data privacy and security grow, RFID systems will likely incorporate more advanced security features, such as encryption, authentication, and tamper-evident technology, to protect sensitive information and prevent unauthorized access.

- Increased adoption in various industries: As the benefits of RFID technology become more widely recognized, its adoption is expected to increase across various industries, including healthcare, retail, and logistics, further driving innovation and growth in the field.

ASC Software: Your Partner in RFID Tracking Solutions for Distribution and Manufacturing Operations

As an industry professional looking to implement RFID technology in your manufacturing processes, partnering with a reliable and experienced RFID solutions provider is crucial. ASC Software is a trusted name in the field, offering integrated RFID solutions for distribution and manufacturing operations.

ASC Software’s flagship product, ASCTrac® WMS, is an RFID-enabled Warehouse Management System that caters to the needs of businesses working with trading partners such as the DOD, Walmart, Best Buy, and Target. With years of experience and certified RFID personnel, ASC Software provides expert guidance and support to help clients navigate the complexities of RFID implementation.

Key features of ASCTrac® WMS include:

- Built-in standard RFID EPC Global and DOD tag creation: ASCTrac® WMS simplifies the “tag-and-ship” process and ensures that the correct data is populated in the required EDI fields.

- Fully integrated data: ASCTrac® WMS combines RFID labeling requirements with an easy-to-use process, streamlining your operations and improving your bottom line.

- RFID hardware compatibility: ASCTrac® WMS fully supports the use of proper RFID hardware in mobile handheld scanners for scanning or reading RFID tags.

In addition to the base product, ASCTrac® WMS offers optional RFID tag reader modules for various purposes, such as inbound and outbound scanning, pack out verification, and pallet verification. These hands-off RFID scanning solutions ensure 100% verification and eliminate the need for operator entry. To implement dock door pallet scanning or case-level scanning, additional RFID solutions are available, which require proper engineering and testing for all scanning portals.

If you have questions or need more information about ASC Software’s RFID solutions, don’t hesitate to reach out and learn how their expertise can benefit your manufacturing operations.

Conclusion

RFID technology has proven to be a game-changer for manufacturing processes, offering significant benefits such as improved efficiency, accuracy, and cost savings. As outlined in this guide, adopting RFID technology can be a complex undertaking, requiring careful planning, implementation, and ongoing support. It is recommended that industry professionals partner with an experienced provider like ASC Software to ensure a smooth transition and to maximize the benefits of RFID technology. By leveraging the expertise of an experienced provider and staying current with the latest advancements in RFID technology, manufacturers can position themselves for success in an ever-changing industry.

Frequently Asked Questions about RFID in Manufacturing

What Is the Main Difference Between Active and Passive RFID Tags?

Active RFID tags contain an internal power source for transmitting data over longer distances, and passive RFID tags use energy emitted by an RFID reader for transmitting data and are generally more cost-effective and energy-efficient.

Can RFID Technology Be Used in Harsh Environments?

Yes, certain RFID tags are designed to withstand harsh environments, including extreme temperatures, moisture, and chemical exposure. It’s essential to select the appropriate RFID tags for your specific manufacturing conditions.

How Do RFID Readers and Antennas Work?

RFID readers emit radio frequency waves that power passive RFID tags and enable them to transmit data. RFID antennas are used to enhance the range and accuracy of RFID readers, ensuring reliable communication between the reader and the tagged items.

How Can I Improve the Accuracy of My RFID System?

Regular maintenance, proper training, and continuous monitoring of your RFID system can help ensure its accuracy and effectiveness. Additionally, using high-quality RFID equipment and integrating your RFID system with other manufacturing technologies can further enhance its performance.

What Is the Difference Between an Active RFID Tag and a Passive RFID Tag, and Which Is Best for My Manufacturing Needs?

An active RFID tag has an internal power source and emits a continuous signal, enabling real-time tracking over long distances. A passive tag, on the other hand, does not have a built-in power source and relies on the energy emitted by an RFID reader to transmit data.

Passive RFID asset tracking is generally more cost-effective and energy-efficient, making it the preferred choice for most manufacturing applications. However, the best option between a passive tag and an active RFID-based system depends on your specific needs, such as read range, real-time tracking, and budget.