In today’s competitive business landscape, effective shop floor control is crucial for optimizing operations management. By implementing the right strategies and leveraging technology, businesses can achieve improved production efficiency, enhanced quality control, and increased operational transparency. This article explores the key strategies and benefits of shop floor control, as well as the challenges businesses may face and the future of this essential aspect of operations management.

Understanding Shop Floor Control in Operations Management

Defining Shop Floor Control

Shop floor control refers to the process of managing and controlling activities that occur on the shop floor, where production takes place. It involves monitoring and coordinating all aspects of production, such as scheduling, resource allocation, workflow management, and performance tracking.

Effective shop floor control relies on real-time data collection and analysis to make informed decisions and adjustments to optimize production processes. By utilizing technologies such as Internet of Things (IoT) devices and data analytics software, manufacturers can gain valuable insights into shop floor operations, identify bottlenecks, and improve overall efficiency.

The Role of Shop Floor Control in Operations Management

Shop floor control plays a critical role in ensuring smooth operations and optimal utilization of resources. It enables businesses to effectively plan, execute, and monitor production activities to meet customer demands, minimize costs, and maximize productivity.

Furthermore, shop floor control is essential for maintaining quality standards and ensuring compliance with industry regulations. By implementing robust quality control measures and tracking production metrics, companies can consistently deliver high-quality products to customers while adhering to safety and regulatory requirements.

Essential Strategies for Effective Shop Floor Control

Implementing Real-Time Data Collection

Real-time data collection is a fundamental strategy for effective shop floor control. By capturing data directly from machines, sensors, and other production equipment, businesses gain immediate visibility into production processes. This data can be used to track performance, identify bottlenecks, and make data-driven decisions for process improvements.

Moreover, real-time data collection enables businesses to monitor key performance indicators (KPIs) in real-time, allowing for quick adjustments to be made to optimize production efficiency. By leveraging advanced analytics tools, businesses can also predict maintenance needs and prevent costly downtime by addressing issues proactively.

Enhancing Communication and Collaboration

Effective communication and collaboration are crucial for successful shop floor control. By fostering clear lines of communication between different teams involved in production, businesses can ensure that everyone is aligned and working towards common goals. This can include implementing digital communication tools, conducting regular meetings, and providing training for effective collaboration.

In addition, fostering a culture of open communication and collaboration can lead to increased employee engagement and morale. When employees feel valued and heard, they are more likely to contribute innovative ideas and solutions to improve shop floor operations, ultimately driving continuous improvement.

Streamlining Workflow Processes

Streamlining workflow processes is another essential strategy for efficient shop floor control. By analyzing and optimizing the entire production workflow, businesses can identify and eliminate bottlenecks, reduce cycle times, and improve overall productivity. This can involve implementing lean manufacturing principles, standardizing work procedures, and using automation technologies.

Furthermore, streamlining workflow processes can lead to cost savings and improved quality control. By reducing unnecessary steps and optimizing resource allocation, businesses can achieve higher levels of efficiency and consistency in their production processes, ultimately enhancing customer satisfaction and competitiveness in the market.

The Benefits of Shop Floor Control

Improved Production Efficiency

One of the significant benefits of shop floor control is improved production efficiency. By effectively managing resources, schedules, and workflows, businesses can minimize downtime, reduce idle time, and ensure that production processes run smoothly. This leads to increased output and reduced costs.

Furthermore, with shop floor control, businesses can implement lean manufacturing principles to streamline operations and eliminate waste. By optimizing production processes and reducing unnecessary steps, companies can achieve higher levels of efficiency and productivity.

Enhanced Quality Control

Shop floor control also plays a crucial role in maintaining and enhancing quality control. By closely monitoring production processes and implementing quality control measures, businesses can identify and address issues in real-time. This ensures that products meet or exceed customer expectations and reduces the risk of defects or recalls.

In addition, by leveraging shop floor control systems, companies can track and trace products throughout the manufacturing process. This end-to-end visibility enables swift identification of any quality issues, allowing for prompt corrective action and preventing substandard products from reaching the market.

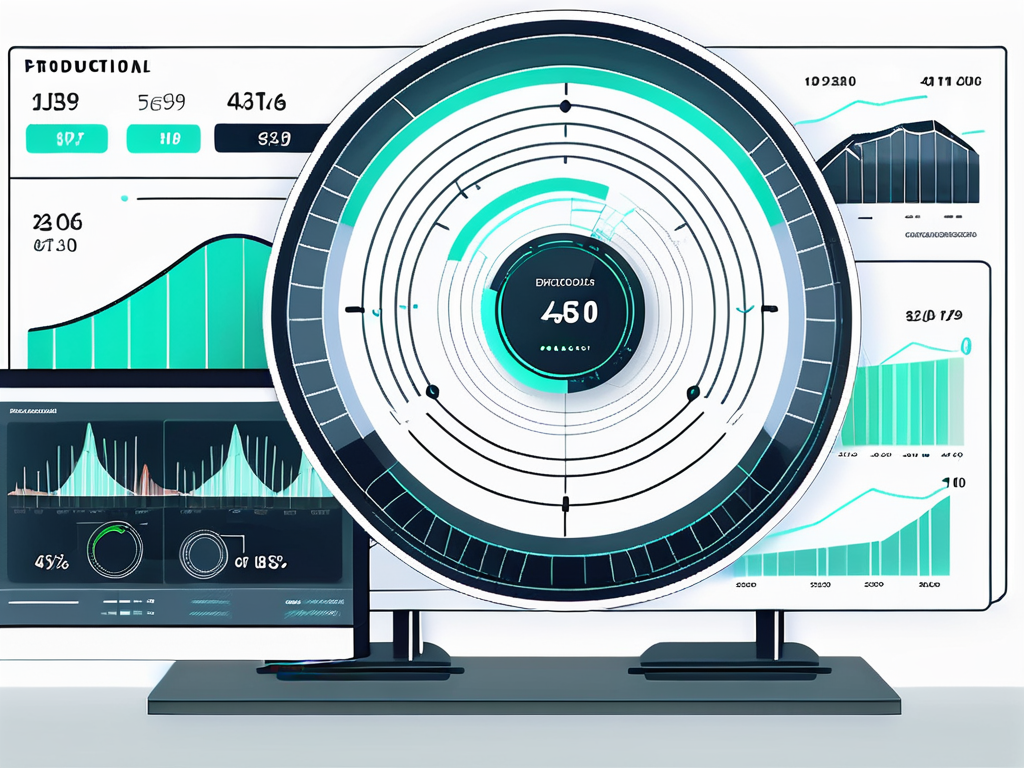

Increased Operational Transparency

Another key benefit of shop floor control is increased operational transparency. By capturing and analyzing real-time data, businesses gain clear visibility into production activities, performance metrics, and resource utilization. This enables better decision-making, enables the identification of areas for improvement, and fosters a culture of continuous improvement.

Moreover, operational transparency facilitated by shop floor control systems enhances collaboration among different departments within an organization. By sharing real-time data and insights, teams can work together more effectively to address challenges, optimize processes, and drive overall business success.

Overcoming Challenges in Shop Floor Control

Addressing Common Obstacles

Despite the benefits, businesses may face challenges when implementing shop floor control. Common obstacles include resistance to change, lack of employee buy-in, and legacy systems that are not compatible with modern shop floor control technologies. To overcome these challenges, organizations need to invest in change management strategies, provide training and support for users, and gradually transition to new technologies.

Resistance to change is a natural response when introducing new systems and processes in any organization. Employees may feel uncertain about how the changes will impact their roles and responsibilities. To address this, management should communicate openly about the reasons for the change, involve employees in the decision-making process, and highlight the benefits that the new shop floor control system will bring to the organization as a whole.

Leveraging Technology for Better Control

Technological advancements present opportunities for businesses to overcome shop floor control challenges. By leveraging technologies such as Industrial Internet of Things (IIoT), cloud computing, and advanced analytics, businesses can enhance visibility, automate data collection and analysis, and enable real-time decision-making. Adopting these technologies can help businesses achieve better control and optimize their operations.

The Industrial Internet of Things (IIoT) allows for the interconnectivity of machines, sensors, and devices on the shop floor, enabling real-time monitoring and data exchange. This connectivity provides valuable insights into machine performance, production efficiency, and maintenance needs, allowing businesses to make informed decisions to improve overall productivity. Cloud computing offers scalability and flexibility in data storage and processing, ensuring that shop floor data is securely stored and easily accessible for analysis and decision-making. Advanced analytics tools enable businesses to derive meaningful insights from the vast amount of data collected on the shop floor, empowering them to identify trends, predict maintenance issues, and optimize production processes for increased efficiency.

The Future of Shop Floor Control in Operations Management

Emerging Trends and Innovations

The future of shop floor control is shaped by emerging trends and innovations. For example, the integration of artificial intelligence and machine learning technologies can enable predictive maintenance, optimize production scheduling, and improve overall efficiency. Smart manufacturing concepts, such as digital twins and virtual reality, also hold promise for further advancements in shop floor control.

Artificial intelligence (AI) and machine learning (ML) are revolutionizing the way businesses manage their shop floor operations. By analyzing vast amounts of data, AI algorithms can identify patterns and predict maintenance needs, allowing businesses to proactively address issues before they become costly problems. ML algorithms can also optimize production scheduling by continuously learning from historical data and making real-time adjustments based on changing conditions. This not only improves efficiency but also reduces downtime and minimizes production delays.

In addition to AI and ML, smart manufacturing concepts like digital twins and virtual reality are transforming shop floor control. Digital twins are virtual replicas of physical assets, allowing businesses to simulate and test different scenarios before implementing them in the real world. This enables businesses to identify potential bottlenecks, optimize processes, and make informed decisions without disrupting production. Virtual reality, on the other hand, provides an immersive and interactive experience that can enhance training programs, improve safety protocols, and facilitate remote collaboration. By leveraging these technologies, businesses can achieve higher productivity, better quality control, and greater operational agility.

Preparing for the Future of Operations Management

As shop floor control continues to evolve, businesses need to prepare for the future of operations management. This includes investing in research and development, staying updated with industry trends and best practices, and fostering a culture of innovation. By taking proactive steps, businesses can position themselves to adapt and thrive in the ever-changing operational landscape.

Investing in research and development is crucial for staying ahead in the rapidly evolving field of operations management. By allocating resources to explore new technologies and methodologies, businesses can gain a competitive edge and drive innovation within their organization. This can involve collaborating with academic institutions, partnering with technology providers, or establishing in-house innovation labs. By embracing a culture of continuous learning and experimentation, businesses can stay at the forefront of industry advancements and be better equipped to navigate future challenges.

Staying updated with industry trends and best practices is equally important. The field of operations management is constantly evolving, with new technologies and methodologies emerging regularly. By actively participating in industry conferences, workshops, and forums, businesses can stay informed about the latest trends and learn from industry experts. Networking with peers and competitors can also provide valuable insights and foster collaboration, leading to mutually beneficial partnerships and knowledge sharing.

In conclusion, shop floor control plays a crucial role in operations management. By implementing key strategies such as real-time data collection, enhancing communication and collaboration, and streamlining workflow processes, businesses can achieve improved production efficiency, enhanced quality control, and increased operational transparency. While challenges may arise, leveraging technology and preparing for the future can help businesses stay ahead in the competitive business environment. With effective shop floor control, businesses can optimize their operations and drive sustained growth and success.