In today’s competitive business landscape, maximizing efficiency is crucial for success. One area where companies can achieve significant gains in efficiency is by integrating shop floor control with ERP systems. This article will explore the basics of shop floor control and ERP systems, discuss the importance of integration, outline the steps to successful integration, examine how to measure the success of integration, and highlight future trends in this field.

Understanding the Basics of Shop Floor Control and ERP Systems

Before delving into the details of integration, it is important to understand what shop floor control and ERP systems are and their respective roles in business.

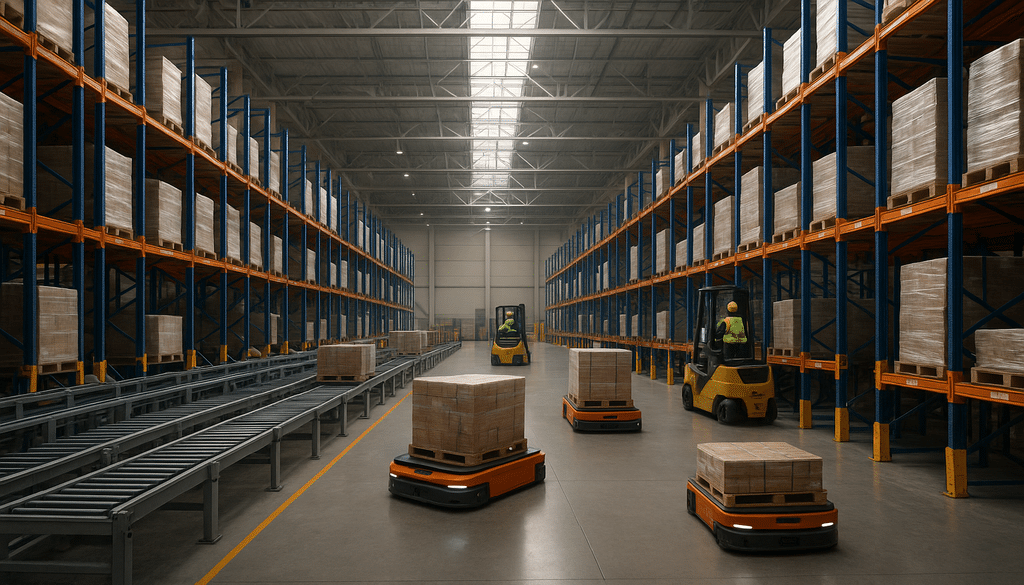

Shop floor control is a crucial aspect of manufacturing operations that involves overseeing and managing the activities on the production floor. It encompasses a wide range of tasks, including production scheduling, inventory management, quality control, and equipment maintenance. Effective shop floor control ensures that production processes run smoothly, resources are utilized efficiently, and products meet quality standards.

Defining Shop Floor Control

Shop floor control refers to the activities and processes involved in managing and controlling the manufacturing operations on the shop floor. It includes tasks such as production scheduling, inventory control, quality assurance, and machine maintenance.

Implementing shop floor control systems can help manufacturers optimize their production processes, minimize downtime, and enhance overall productivity. By tracking real-time data, identifying bottlenecks, and automating routine tasks, companies can improve operational efficiency and meet customer demands more effectively.

The Role of ERP Systems in Business

ERP, or Enterprise Resource Planning, systems are software solutions that provide integrated management of core business processes such as finance, human resources, procurement, sales, and customer relationship management. ERP systems enable companies to streamline operations, improve communication, and make data-driven decisions.

Furthermore, ERP systems facilitate cross-departmental collaboration by centralizing data and standardizing processes across the organization. By consolidating information from various departments into a single database, ERP systems enable seamless communication and coordination, leading to improved efficiency and transparency. Additionally, ERP systems offer advanced reporting and analytics capabilities, allowing businesses to gain valuable insights into their operations and performance metrics.

The Importance of Integration for Efficiency

Integrating shop floor control with ERP systems offers several benefits for companies striving to maximize efficiency.

Efficiency is a crucial aspect of any business operation. It determines the speed and accuracy with which tasks are completed, ultimately impacting the overall productivity and profitability of a company. In today’s fast-paced and competitive business landscape, organizations are constantly looking for ways to streamline their processes and enhance their operational efficiency. One effective approach is integrating shop floor control with ERP systems.

Benefits of Integrating Shop Floor Control with ERP Systems

One of the key benefits of integration is real-time visibility and access to accurate data. By connecting shop floor control with ERP systems, managers can monitor production status, track inventory levels, and analyze performance metrics in real-time. This enables proactive decision-making, reduces delays, and optimizes resource allocation.

Imagine a scenario where a company’s production manager needs to make an urgent decision regarding the allocation of resources. Without integration, they would have to rely on outdated reports or manually collect information from different sources, leading to delays and potential errors. However, with integration in place, the manager can access real-time data, enabling them to make informed decisions promptly.

Integration also eliminates manual data entry and reduces errors. Instead of relying on paper-based systems or manual data transfer, information is automatically captured and updated across both systems. This saves time, minimizes the risk of errors, and ensures data consistency.

Furthermore, integration enables seamless communication and collaboration between different departments. With shop floor control and ERP systems working together, employees in production, sales, finance, and other departments can access relevant information and work towards common goals. This improves coordination, reduces bottlenecks, and fosters cross-functional collaboration.

For instance, imagine a scenario where the production department receives a rush order from a customer. With integration in place, the production team can quickly communicate this information to the sales department, enabling them to provide the customer with accurate delivery timelines. This level of collaboration and communication ensures customer satisfaction and strengthens the overall efficiency of the organization.

Potential Challenges in Integration

While the benefits of integration are substantial, there can be challenges in implementing and maintaining a successful integration process.

One common challenge is choosing the right integration approach. There are different methods available, such as point-to-point integration, middleware integration, and service-oriented architecture. Each approach has its advantages and disadvantages, and companies need to carefully assess their requirements and choose the most suitable method.

Another challenge is data synchronization. Ensuring that data is consistently updated and synchronized between shop floor control and ERP systems is critical for accurate decision-making. Data discrepancies can lead to inefficiencies, delays, and costly errors. Implementing robust data synchronization processes and protocols is essential to overcome this challenge.

Lastly, resistance to change can be a hurdle in the integration process. Employees may be accustomed to existing systems and processes, and may resist adopting new technologies and ways of working. Clear communication, training, and support throughout the integration process are crucial for successful adoption and overcoming resistance.

Overcoming these challenges requires a strategic approach and a commitment to continuous improvement. By addressing these challenges head-on, companies can unlock the full potential of integration and achieve enhanced efficiency in their operations.

Steps to Successful Integration

Successfully integrating shop floor control with ERP systems requires careful planning and execution. The following steps can serve as a roadmap for a successful integration process.

Planning for Integration

The first step is to establish clear goals and objectives for the integration process. What specific outcomes do you want to achieve? Identify the key challenges and opportunities, and define the scope of the integration project. Assess the resources needed, both in terms of technology and human resources, and create a detailed project plan with timelines and milestones.

It is also essential to involve relevant stakeholders throughout the planning phase. Collaborate with representatives from production, IT, finance, and other departments to gather input, address concerns, and ensure buy-in.

Implementing the Integration Process

Once the planning phase is complete, it is time to implement the integration process. This involves configuring and customizing the integration software, mapping data fields between the shop floor control and ERP systems, and establishing workflows and rules for data transfer and synchronization.

During this phase, thorough testing and validation are crucial. Conduct comprehensive testing to ensure that data is properly transferred, synchronized, and validated between the systems. Address any issues or errors that arise, and refine the integration process as necessary.

Training and support for employees should also be provided during the implementation phase. Ensure that employees understand the new processes and systems, and provide ongoing support to address any questions or difficulties they may encounter.

Measuring the Success of Integration

Measuring the success of shop floor control and ERP integration is essential to evaluate the efficiency gains and identify areas for further improvement.

Key Performance Indicators for Integration

Key performance indicators (KPIs) can help measure the effectiveness of integration. Some relevant KPIs include: on-time delivery performance, production cycle time, inventory accuracy, defect rate, and overall equipment efficiency. Monitoring these KPIs over time provides insights into the impact of integration on operational performance and helps identify areas for optimization.

Continuous Improvement and Maintenance

Integration is not a one-time process but an ongoing effort. Continuous improvement and maintenance activities are essential to ensure that the integration remains effective and aligned with evolving business needs.

Regularly review the integration processes, identify bottlenecks and areas for improvement, and take corrective actions. Stay up to date with software updates and new technologies in the field of shop floor control and ERP integration. Adopt best practices and leverage automation tools to further optimize the integration process and maximize efficiency.

Future Trends in Shop Floor Control and ERP Integration

The field of shop floor control and ERP integration is constantly evolving, driven by technological advancements and changing business needs.

Technological Advancements and Their Impact

Advancements in technologies such as artificial intelligence, machine learning, and Internet of Things (IoT) are transforming the manufacturing industry. These technologies are increasingly being integrated with shop floor control and ERP systems, enabling predictive maintenance, real-time analytics, and smart decision-making.

For example, IoT sensors can be deployed on machines to collect real-time data on their performance and condition. This data can be automatically integrated with ERP systems, triggering maintenance alerts or optimizing production schedules based on machine health and availability.

Preparing for Future Integration Needs

As technology continues to advance, it is important for companies to prepare for future integration needs. Stay informed about emerging trends and technologies in the field, and assess their potential impact on your operations and competitiveness.

Engage in ongoing research and development activities to explore new integration opportunities. Collaborate with technology partners and vendors to leverage their expertise and stay ahead of the curve. By proactively embracing future integration needs, companies can position themselves for sustained efficiency and competitiveness.

Conclusion

Integrating shop floor control with ERP systems is a powerful strategy for maximizing efficiency in manufacturing operations. By understanding the basics of shop floor control and ERP systems, recognizing the benefits and challenges of integration, and following a systematic approach to integration, companies can achieve significant gains in productivity, accuracy, and collaboration.

Measuring the success of integration through key performance indicators and embracing continuous improvement and future integration trends further enhances operational efficiency and competitiveness. With the right integration strategy and ongoing commitment to efficiency, companies can unlock the full potential of their shop floor control and ERP systems.