Understanding the Role of Barcodes and QR Codes in Inventory Management

Barcodes and QR codes are pivotal in modern inventory management systems. Barcodes, a familiar sight in retail and logistics, consist of parallel lines of varying widths and spacings that encode data. QR codes, or Quick Response codes, are two-dimensional matrices that can store more information than traditional barcodes. Both technologies serve the primary purpose of automating data capture, thereby minimizing human error and enhancing operational efficiency.

The importance of these technologies cannot be overstated. By automating the data entry process, barcodes and QR codes significantly reduce the likelihood of manual errors that can occur during inventory counts and audits. This automation ensures that data is accurately captured and processed, leading to more reliable inventory records. As a result, businesses can achieve greater accuracy in stock levels, order fulfillment, and overall inventory management.

Key Benefits of Implementing Barcode Inventory Systems

Implementing a barcode inventory system offers numerous benefits that extend beyond mere error reduction. One of the most significant advantages is the improvement in accuracy and speed of inventory processing. Barcodes allow for rapid scanning and data entry, which accelerates inventory handling and reduces the time spent on manual data entry tasks.

Moreover, barcode systems seamlessly integrate with inventory management software, providing real-time updates and insights into stock levels and movements. This integration enables businesses to maintain accurate inventory records, optimize stock levels, and improve order fulfillment rates. The result is a more efficient supply chain that can respond quickly to changes in demand and minimize stockouts or overstock situations.

Additionally, barcode systems enhance traceability and accountability within the supply chain. By providing a unique identifier for each item, barcodes facilitate tracking from the point of manufacture to the end consumer. This traceability is crucial for industries such as pharmaceuticals and food, where regulatory compliance and safety are paramount.

QR Codes: Taking Inventory Management to the Next Level

While barcodes have been a staple in inventory management, QR codes offer unique advantages that can elevate inventory processes. Unlike barcodes, which are typically one-dimensional, QR codes are two-dimensional and can store a wealth of information, including URLs, text, and other data types. This capability makes QR codes more versatile and suitable for complex inventory systems.

For instance, QR codes can be used to store detailed product information, such as batch numbers, expiration dates, and handling instructions. This feature is particularly beneficial in industries like healthcare and manufacturing, where detailed tracking and compliance are required. A notable example is a healthcare facility using QR codes to track medical supplies, ensuring that each item is used before its expiration date and that inventory levels are accurately maintained.

Automating Inventory Audits with Barcodes and QR Codes

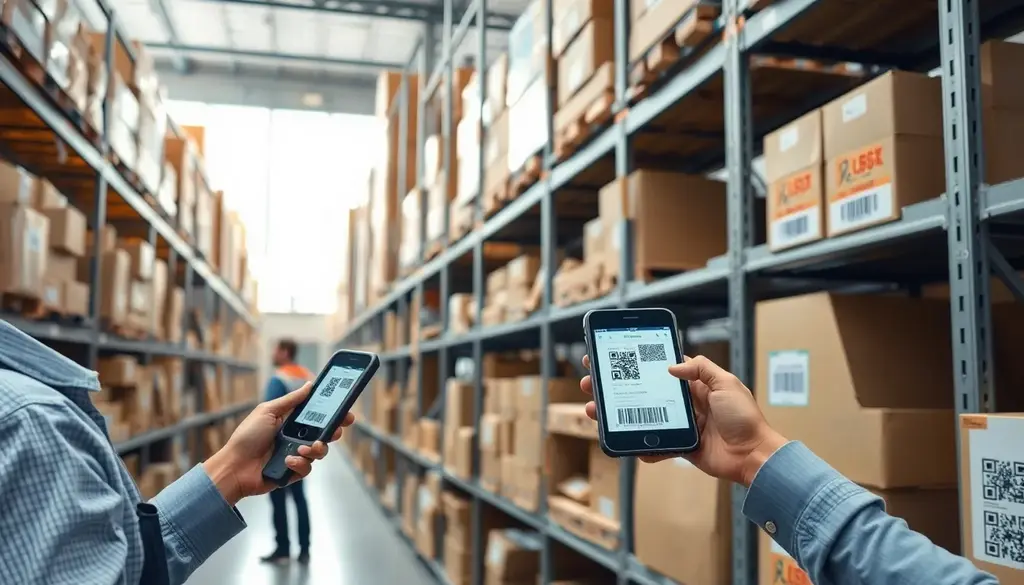

Inventory audits are a critical aspect of inventory management, ensuring that physical stock levels match recorded data. Barcodes and QR codes simplify and automate the audit process, reducing the time and effort required for manual counts. By scanning items with handheld devices or mobile apps, businesses can quickly verify inventory levels and identify discrepancies.

The impact of these technologies on perpetual inventory management is profound. With real-time data accuracy, businesses can maintain up-to-date inventory records, enabling them to make informed decisions about purchasing, stocking, and order fulfillment. This level of accuracy is essential for maintaining customer satisfaction and optimizing supply chain operations.

Integrating Barcode and QR Code Technology with Inventory Tracking Software

Integrating barcode and QR code technology with existing inventory tracking software is a strategic move that can enhance overall inventory management. The integration process involves several key steps, starting with selecting compatible hardware and software solutions. Businesses should choose systems that support real-time data updates and offer user-friendly interfaces to facilitate smooth adoption.

Software solutions that best support barcode and QR code integration often include features such as automated data capture, comprehensive reporting, and seamless connectivity with other business systems. These features enable businesses to gain valuable insights into inventory trends, optimize stock levels, and improve operational efficiency.

Overcoming Challenges in Barcode and QR Code Implementation

While the benefits of barcodes and QR codes are clear, implementing these technologies can present challenges. Common issues include the initial cost of hardware and software, integration complexities, and the need for staff training. To overcome these challenges, businesses should conduct thorough planning and analysis to ensure a smooth transition.

Best practices for successful implementation include investing in quality equipment, selecting reliable software vendors, and providing comprehensive training to staff. Regular maintenance and updates are also crucial to ensure the technology remains effective and continues to deliver value.

ASC Software: Powering Smarter Inventory Management

At ASC Software, we specialize in delivering cutting-edge inventory management solutions that harness the power of barcodes and QR codes to drive accuracy, efficiency, and automation. Our software solutions are designed to seamlessly integrate with barcode scanning systems, ensuring real-time data capture and minimizing human error in inventory tracking.

With decades of expertise in supply chain technology, ASC Software provides scalable, customizable solutions that empower businesses of all sizes—from small enterprises to large-scale distribution centers. Whether you’re looking to enhance stock visibility, streamline warehouse operations, or optimize order fulfillment, our advanced inventory management software ensures precise control over every aspect of your supply chain.

By leveraging ASC Software’s robust barcode and QR code-enabled platforms, businesses can reduce costly stock discrepancies, automate inventory audits, and improve overall operational efficiency. Our commitment to innovation and customer success means we continuously develop solutions that adapt to the evolving needs of modern warehousing, manufacturing, and retail industries.

Conclusion

Barcodes and QR codes play a transformative role in reducing errors and optimizing inventory management. By automating data capture and improving accuracy, these technologies enable businesses to streamline operations and enhance supply chain efficiency. For warehouse managers and logistics professionals, adopting barcodes and QR codes is a strategic move that can lead to more reliable and efficient inventory processes. As the industry continues to evolve, embracing these technologies will be essential for staying competitive and meeting the demands of modern supply chain management.

Ready to reduce errors, streamline operations, and improve inventory accuracy? ASC Software provides powerful, barcode and QR code-enabled solutions designed to optimize your supply chain. Whether you’re looking to integrate automated tracking, enhance visibility, or boost efficiency, we have the tools to help you succeed.

Contact us today to learn how ASC Software can transform your inventory management system.

Frequently Asked Questions (FAQ)

What are the primary differences between barcodes and QR codes?

Barcodes are typically one-dimensional with varying widths and spacings of parallel lines, used mainly for product identification. QR codes are two-dimensional, can store more data, and are readable from any direction, making them more versatile for various applications.

How do barcodes and QR codes help in reducing human error in inventory management?

These technologies automate data entry processes, significantly reducing the chances of manual errors during inventory counts and audits. They ensure data is accurately captured and processed, leading to more reliable inventory records and improved operational efficiency.

Can small businesses benefit from implementing a barcode inventory system?

Absolutely. Even small businesses can see significant improvements in inventory accuracy and operational efficiency. Implementing a barcode system can help small businesses scale operations, manage resources more effectively, and enhance customer satisfaction by ensuring timely and accurate order fulfillment.

What should be considered when choosing inventory tracking software that supports barcodes and QR codes?

Key considerations include compatibility with existing hardware, ease of integration, user-friendliness, and the ability to support real-time data updates and comprehensive reporting. Additionally, businesses should evaluate the software’s scalability and support services to ensure it meets their long-term needs.

Are there any industries that particularly benefit from QR code inventory management?

Industries with a need for tracking extensive information, such as healthcare, retail, and manufacturing, find QR codes especially beneficial. QR codes’ capacity to hold more data and support complex inventory systems makes them ideal for environments where detailed tracking and compliance are critical, such as tracking medical supplies or managing large product catalogs in retail.