Enterprise Resource Planning (ERP) and Material Requirements Planning (MRP) are two systems that are often confused with one another. They both deal with the management of resources within a company, but they are actually quite different.

In this article, we will discuss the differences between ERP vs MRP and how the two systems are related. We’ll also describe how they can both be used to help your business run more efficiently.

Let’s begin by discussing each system. Then, we’ll compare and contrast the two.

What is a Material Requirements Planning (MRP) System?

A Material Requirements Planning (MRP) system is a computer-based inventory management software used to manage materials required in manufacturing processes. MRP systems help manufacturing businesses ensure they have the raw materials required to produce their products.

How Do MRP Systems Work?

MRP systems are used to manage the materials that are required for manufacturing products. The system keeps track of the quantities of each material that is needed and when it is needed. This information is used to generate Work Orders (WO) and Purchase Orders (POs) for the materials.

Purchase orders are then sent to suppliers. Once the materials are received, they are entered into the MRP system. The system then uses this information to generate production schedules. The production schedules detail when each product should be manufactured and in what quantity.

The MRP system is constantly being updated with information about the materials that are available, the quantities of each material that are needed, and the production schedules. This information is used to generate reports that can be used by managers to make decisions about manufacturing processes.

A Brief History of MRP Systems

The first MRP systems were developed in the 1950s and ’60s by Rolls Royce and General Electric. However, they weren’t available to the public. In the mid-1970’s Joseph Orlicky, considered to be the father of MRP, wrote his famous book, “Material Requirements Planning.” In it, he outlined the benefits of using MRP.

By the early 1980s, thousands of companies were using MRP systems.

Modern MRP Software Systems

Today, MRP software systems are used within manufacturing operations of all sizes and are much more sophisticated than earlier systems. Systems can be integrated with other software applications within your business, such as your financial system. Some MRPs can also be accessed from mobile devices, such as smartphones and tablets.

Benefits of Using an MRP System

There are many benefits of using an MRP system to improve manufacturing processes, including:

- Improved inventory management.

- Reduced production costs.

- Improved decision-making.

- Improved customer satisfaction.

Disadvantages of Using an MRP System

There are some disadvantages of using an MRP, including:

- The initial cost of implementing an MRP can be expensive.

- MRP systems can be somewhat complex and difficult to set up.

Alternatives to Using an MRP System

There are several alternatives to using an MRP, including:

- Using a manual system: This is the most basic way to manage materials. It requires keeping track of information on paper or in Excel spreadsheets.

- Using a Kanban system: This is a visual way to manage materials. It uses cards to track information about materials.

- Using an ERP system: This is the most comprehensive way to manage materials. It includes MRP functionality and can be customized to fit the specific needs of each company.

What is Enterprise Resource Planning (ERP) Software?

Enterprise Resource Planning (ERP) software is used by organizations to help manage a wide range of business activities. This can include accounting, procurement, project management, risk management, compliance, and supply chain operations.

ERP systems process data and connect various aspects of the business to optimize performance and efficiency. Today, ERP systems are indispensable to countless businesses of all sizes and in all industries.

A Brief History of ERP Software

The first ERP system is believed to have been developed in the 1960s by IBM and a tractor company called J.I. Case. ERP systems were soon developed by other manufacturers as in-house systems. However, these initial systems were large, expensive, and took dedicated teams of experts to maintain.

It wasn’t until the 1980’s that the first manufacturing resource planning (MRP II) systems appeared. These took MRP beyond the scope of inventory and raw materials procurement. These new systems allowed the other departments involved in manufacturing to be integrated.

In the 1990s the term Enterprise Resource Planning was adopted. This led to ERP systems as we now know them. These modern ERP systems act as unified databases of information from across a company.

How Do ERP Systems Work?

ERP systems are used to manage and connect many areas of a business. This can include accounting, inventory control, human resources, customer relationship management (CRM), and more. Data from each of these areas is processed and stored in a central database. This data can then be harnessed for increased efficiency in operations across the business.

What Are the Benefits of Using an ERP System?

There are many benefits of using an ERP system, including:

- Improved decision making: ERP systems provide managers with real-time information about all aspects of the business. This helps managers make better decisions about where to allocate resources.

- Increased efficiency: ERP systems automate many business processes. This reduces the need for manual input and increases the accuracy of information.

- Cost savings: ERP systems can help businesses save money through better inventory management, procurement management, improved vendor relationships, and more.

- Improved customer service: ERP systems help businesses keep track of customer orders and inventory levels as well as integrate with customer relationship management systems. This helps businesses provide better customer service by ensuring that products are available and customers are satisfied.

What Are the Disadvantages of Using an ERP System?

There are some disadvantages of using an ERP system, including:

- High cost: ERP systems can be expensive to implement and maintain.

- Complexity: ERP systems are complex and can be difficult to use.

- Requires extensive training: Employees often need extensive training to use an ERP system.

Who Uses ERP Systems?

ERP is popular among businesses engaged in the supply chain, manufacturing, and distribution process. However, ERPs are used by a wide range of companies, including healthcare organizations, nonprofit organizations, construction firms, hotels, and more.

ERP vs. MRP: The Relationship Between the Two Systems

Both ERP and MRP systems are used to manage resources. However, they serve businesses in different ways.

As mentioned, an ERP system is a software used to manage the various resources of a business, including materials, money, and people. ERP systems track information about all aspects of a business, from customer orders to inventory levels.

Whereas, an MRP is a type of material requirements planning system. It is a software application that is used to manage the materials used in manufacturing. MRP systems track information about the materials needed to produce a product.

Key Differences Between ERP and MRP Systems

- ERPs are more comprehensive than MRPs.

- MRPs are less expensive and less complex than ERPs.

- ERPs track information about all aspects of a business, from customer orders to inventory levels. MRPs track information about the materials needed to produce a product.

- ERPs are typically used by businesses of all sizes. MRPs are typically used by businesses that manufacture products.

Can ERP and MRP Systems Be Used Together?

Yes, ERP and MRP systems can be used together. In fact, they are often used together to provide a comprehensive solution for managing all aspects of a business.

For example, an ERP can be used to track customer orders and inventory levels. While an MRP can be used to track the materials needed to produce a product.

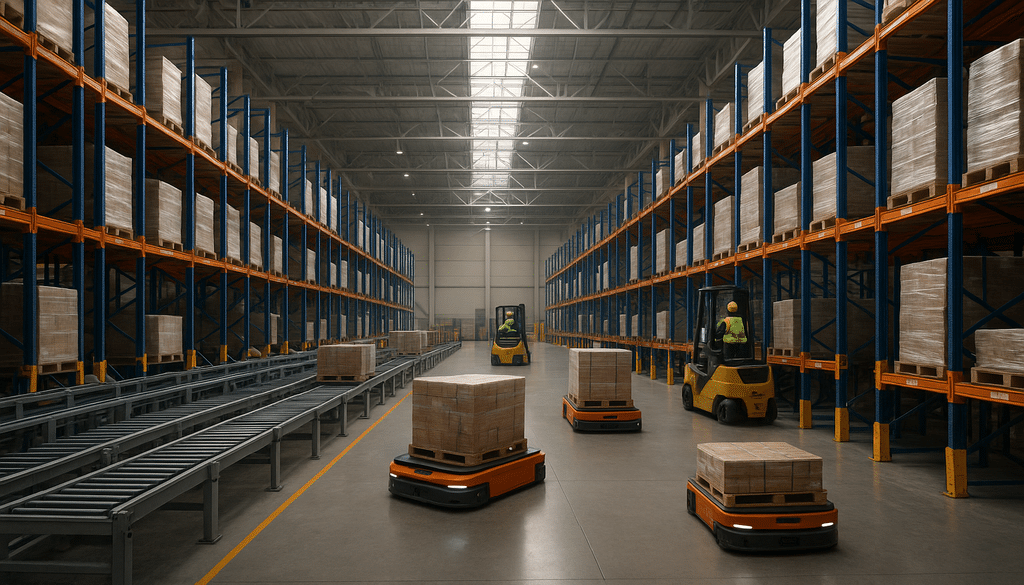

MRP vs. WMS (Warehouse Management System)

The main difference between warehouse management systems (WMS) and MRP systems is the type of information they track. A WMS is software that is used to track and manage operations in a warehouse. Functions typically include inventory tracking, picking, receiving, and putaway.

An MRP system is software used to track and manage the raw materials needed to produce a product. Therefore, an MRP system is typically used by businesses that manufacture products. WMS software is used by warehouse operators across the supply chain and logistics industries.

ERP vs. WMS

As we said, a WMS is used to manage operations in a warehouse.

On the other hand, an ERP is a software that tracks and manages all aspects of a business, from customer orders to inventory levels and accounting.

ERP, MRP, and WMS systems can all be used in conjunction to provide a comprehensive solution for managing all aspects of a warehouse business. But many businesses may not need a system that complex.

Material Requirements Planning (MRP) with ASCTrac®

ASCTrac is a comprehensive, web-based software application that includes powerful tools for material requirements planning (MRP). ASCTrac MRP automatically calculates the materials needed to produce a product, based on the bill of materials and production schedule. It also takes into account inventory levels, safety stock, and lead times.

ASCTrac® Connectivity to ERP, IIoT, eCommerce, and More

In addition to MRP, ASCTrac includes tools for enterprise resource planning (ERP), connectivity to Industrial Internet of Things (IIoT), and eCommerce. ASCTrac MRP is easy to use and can be customized to fit the specific needs of your business.

Contact us today to learn more about ASCTrac and how it can help increase efficiency and provide greater control over your business.

Conclusion

When considering ERP vs. MRP, both are software solutions that can help businesses manage their operations. The main difference between the two is that ERPs are designed to track and manage all aspects of a business, while MRP systems are designed specifically for businesses that manufacture products.

Both types of systems have their own advantages and disadvantages, so it’s important to assess your needs before deciding which one is right for your business.

If you’re not sure which type of system is right for your business, get in touch with us to learn more about ERP vs. MRP and ASCTrac integrations. We will help assess your needs and recommend the best solutions for your business.

FAQs

What is MRP ERP System?

Both MRP and ERP systems are software solutions that help businesses manage their operations. The main difference between the two is that MRPs are designed specifically for businesses that manufacture products, while ERPs are designed to track and manage all aspects of a business.

Does ERP Include MRP?

ERPs typically include MRP functionality. However, some businesses may choose to use a separate MRP and ERP solution.

What is Kanban?

Kanban is a system for managing workflows. It is based on the principle of just-in-time production, which means that only the amount of work needed to meet demand is produced. Kanban helps businesses optimize their production processes and avoid waste.

Kanban can be used with any type of work, from manufacturing to software development. It is a flexible system that can be customized to fit the specific needs of your business.

What is Material Requirements Planning (MRP) Software?

Material requirements planning (MRP) software is a type of business management software that helps businesses plan and manage their inventory. This software is used to track information about all aspects of a business, from customer orders to inventory levels. This information is stored in a central database.

The terms MRP system and MRP software are often used interchangeably.

How are ERP and MRP used in supply chain management?

ERP and MRP systems are both used in supply chain management. ERPs track and manage all aspects of a business, while MRPs focus specifically on the manufacturing industry.

Supply chain management is the process of managing the flow of goods and materials from suppliers to customers. It includes the planning, coordination, and control of all activities in the supply chain.

Either an ERP or MRP system can help businesses optimize their supply chains by providing visibility into all aspects of the operation. This information can be used to make decisions about production, inventory, shipping, and more.

ERP vs MRP: Which is better for my business?

The answer to this question depends on the specific needs of your business. An ERP solution is designed to track and manage all aspects of a business, while MRPs are designed specifically for manufacturing operations.

Both types of systems have their own advantages and disadvantages, so it’s important to assess your needs before deciding which one is right for your business.

What is MRP in Production Planning?

Material requirements planning (MRP) is a type of production planning that helps businesses in the manufacturing industry plan and manage their inventory. MRP systems are used to track information about all aspects of a business, from customer orders to inventory levels.