The global supply chain is evolving rapidly, and automation is no longer a luxury but a necessity for warehouses striving for efficiency and competitiveness. As e-commerce demand grows and labor constraints become more prevalent, businesses must find solutions that streamline warehouse operations while maintaining accuracy and cost-effectiveness.

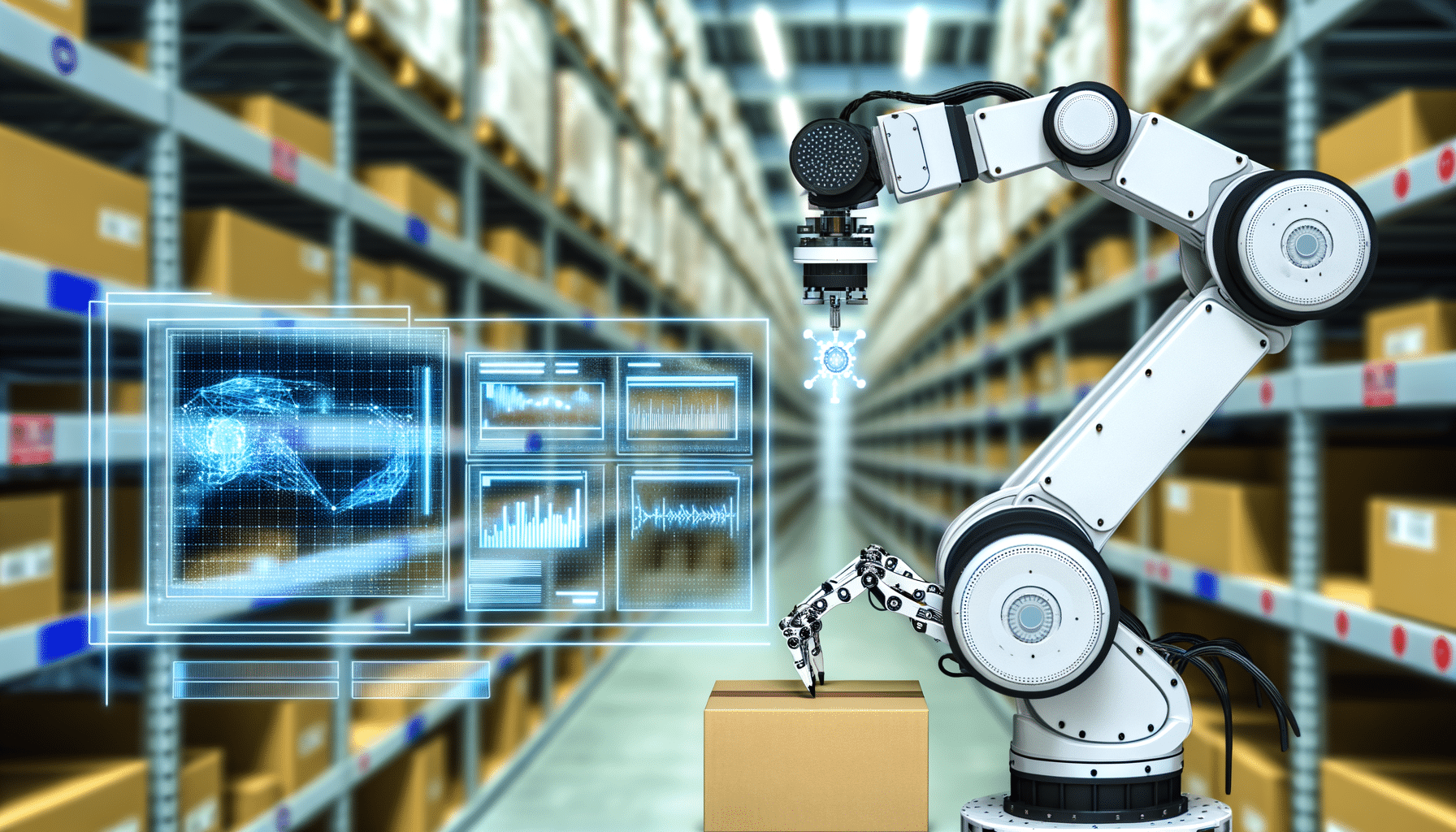

Automated picking systems have emerged as one of the most impactful innovations, significantly improving order fulfillment speed, reducing errors, and lowering operational costs. Utilizing technologies such as robotic picking, conveyors, and advanced order-picking mechanisms, businesses can optimize their warehouse processes to meet increasing customer expectations.

This article explores the role of automated picking systems, the different technologies available, and their benefits in warehouse efficiency. We’ll also discuss key considerations for implementation and the future trends shaping warehouse automation.

Understanding Automated Picking Systems

Automated picking systems refer to technology-driven processes that streamline the selection and retrieval of products in a warehouse. These systems replace or enhance manual picking methods by leveraging robotics, AI, and computer vision to improve efficiency and accuracy.

Manual vs. Automated Picking

- Manual picking: Relies on human workers to retrieve and prepare items for shipment, often leading to inefficiencies, errors, and higher labor costs.

- Automated picking: Utilizes advanced systems such as robots, conveyors, and AI to optimize item retrieval, reducing errors and speeding up the process.

Key Benefits of Automated Picking Systems

- Increased speed: Automated systems can significantly reduce order processing times.

- Higher accuracy: Minimizes picking errors and improves order fulfillment reliability.

- Lower labor costs: Reduces dependency on large human workforces while optimizing workforce allocation.

- Improved efficiency: Keeps warehouse operations running smoothly with minimal downtime.

Types of Automated Picking Solutions

Robotic Picking Systems

Robotic picking solutions use AI-powered robotic arms to identify, grasp, and move items with precision. These robots can perform repetitive tasks much faster than human workers while maintaining high accuracy levels, minimizing order errors, and handling a wide range of product types.

Pick-to-Light and Put-to-Light Systems

Pick-to-Light and Put-to-Light systems use light indicators to guide workers in selecting the correct items from storage locations. Workers scan a barcode, and lights direct them to the required bin, ensuring faster and more accurate order fulfillment.

Goods-to-Person (GTP) Systems

GTP systems bring items directly to workers using automated storage and retrieval systems (AS/RS), conveyors, and robotic shuttles. By eliminating unnecessary movement, these systems improve efficiency and reduce fatigue-related errors.

Voice-Picking Technology

Voice-picking solutions integrate with warehouse management systems (WMS) and guide workers using audio commands. Workers wear headsets and receive verbal instructions, allowing for hands-free picking that enhances speed and accuracy.

How Automated Picking Enhances Warehouse Efficiency

- Reduction in picking errors: Automated systems drastically reduce mispicks and order inaccuracies, leading to improved customer satisfaction.

- Faster order fulfillment: Picking automation increases throughput, making it possible to handle higher order volumes efficiently.

- Minimized labor dependency: Warehouses can operate with fewer workers while maintaining high output levels.

- Seamless WMS integration: Automated picking solutions can integrate with WMS platforms, creating synchronized workflows and real-time inventory updates.

Key Considerations When Implementing Automated Picking Systems

Implementing an automated picking system requires proper evaluation to maximize ROI and ensure smooth integration. Key factors to consider include:

Warehouse Size and Order Volume

Businesses must assess their facility layout, order volume, and SKU diversity to determine which automation solutions best fit their needs.

Technology Selection

Different picking solutions exist, from robotic systems to automated storage and retrieval. Understanding the unique needs of your warehouse will help in selecting the most effective solution.

Cost and ROI

While automation requires upfront investment, businesses must evaluate the long-term savings derived from reduced labor costs, increased throughput, and improved accuracy.

Workforce Training and Transition

Automation doesn’t eliminate the need for human workers; instead, it shifts their roles. Training staff to work alongside automated solutions ensures a smooth transition and maximizes productivity.

Future Trends in Automated Picking and Warehouse Automation

AI and Machine Learning in Predictive Picking

AI is increasingly being used for analyzing order patterns and optimizing picking routes, reducing processing times and improving efficiency.

Advancements in Robotic Picking and AMRs

Autonomous Mobile Robots (AMRs) are becoming more sophisticated, capable of navigating warehouses, retrieving items, and collaborating with workers.

IoT and Real-Time Inventory Tracking

By integrating IoT sensors, warehouses can gain real-time visibility into inventory locations, improving picking accuracy and replenishment efficiency.

Emerging Trends in Supply Chain Automation

End-to-end automation will continue to transform warehouses with connected systems, data-driven insights, and seamless logistics coordination.

Conclusion

The implementation of automated picking systems is a game-changer for modern warehouses, ensuring faster order fulfillment, enhanced accuracy, and lower operational costs. As market demands evolve, businesses that invest in picking automation will stay ahead in logistics and supply chain management.

By leveraging robotic picking, AI-driven solutions, and GTP technologies, warehouses can unlock new levels of efficiency and scalability. Companies looking to streamline operations and improve bottom-line results should explore automation solutions tailored to their unique warehouse needs.

Optimize Your Warehouse with ASC Software

Automation is the key to staying competitive in today’s fast-paced supply chain. ASC Software’s Warehouse Management System seamlessly integrates with automated picking solutions, helping you reduce errors, improve efficiency, and maximize ROI. Whether you’re looking for robotic picking, GTP systems, or other advanced solutions, ASC Software can help you implement the right technology for your warehouse.

Ready to take your warehouse operations to the next level? Contact ASC Software today to learn how our WMS can streamline your picking processes and drive efficiency.